The term LED printer frequently appears in technical specifications, procurement documents, and professional printing discussions. Despite its common use, many readers encounter the term without a clear explanation of what it actually represents.

It is often mentioned as if the meaning were self-evident or casually grouped with other digital printing technologies. As a result, this type of printer are widely recognized by name, yet rarely understood in terms of how the technology works or why it exists.

For beginners, this lack of clarity leads to surface-level assumptions. The printer produces acceptable output, and the internal process feels unimportant.

For experienced users, the issue is different. Information about LED-based printing is often fragmented, simplified, or limited to brief technical notes that omit the broader engineering logic. This makes it difficult to understand what an LED printer represents as a complete printing system.

At a technical level, LED printing is built around a deliberate engineering decision. Instead of relying on complex mechanical motion during image exposure, it uses a fixed arrangement of light-emitting diodes to form images with precision and consistency.

This choice influences mechanical design, long-term reliability, and exposure stability. However, these implications are rarely explained in clear and practical terms.

Rather than treating LED printing as a label or marketing term, this article approaches it as a technical system. The focus is on how the technology operates, how its internal structure affects print behavior, and what its design choices mean in real-world use.

By examining the workflow, components, and engineering decisions behind LED printing, the goal is to provide a grounded understanding of where this technology fits and why it continues to be used in professional environments.

What Is an LED Printer?

An LED printer is a digital electrophotographic device that uses a fixed array of light-emitting diodes to expose an image onto a photosensitive drum. The exposed areas attract toner, which is then transferred to paper and fused using heat and pressure.

This definition captures the core mechanism without reducing the technology to a vague category or oversimplifying how image formation occurs.

In practical terms, the system replaces a moving light source with a stationary row of microscopic LEDs that spans the printable width. Each diode corresponds to a specific position on the page and activates only when required.

This allows the printer to expose an entire line simultaneously rather than scanning across the surface in stages. The result is a controlled and repeatable exposure process that supports stable image formation.

According to technical documentation from :contentReference[oaicite:0]{index=0}, LED-based systems reduce mechanical complexity by eliminating moving exposure components. Fewer moving parts generally translate into reduced wear over long-term use.

From an engineering perspective, this makes the technology well suited for environments where consistent operation is required over extended print cycles.

LED Printing Within Digital Electrophotographic Systems

LED printing belongs to the broader family of electrophotographic processes. These systems rely on electrical charge, controlled light exposure, and toner development to create images.

In an LED-based system, the photoconductive surface is first charged uniformly. The LED array then selectively discharges specific areas to form a latent electrostatic image.

Toner particles are attracted to these exposed regions, creating a visible image that can be transferred and fused onto paper.

What distinguishes LED exposure within this category is not toner chemistry or output method, but the way exposure is achieved. Because the light source is fixed across the page width, exposure occurs in a synchronized and predictable manner.

This approach supports consistent image density and alignment, especially across repeated print jobs, which explains why LED-based output is often associated with stable behavior.

The Engineering Rationale Behind LED Printing

The use of fixed LED exposure reflects an engineering priority rather than a purely visual one. Exposure systems without moving parts are inherently more stable over time.

By removing precise mechanical motion from the exposure stage, the process becomes less sensitive to vibration, alignment drift, and long-term wear.

This design philosophy emphasizes predictability and consistency. Instead of compensating for motion through calibration, the system relies on structural simplicity to maintain uniform results.

For office and professional environments, this balance between precision and durability makes LED printing a technology defined as much by its engineering logic as by its output quality.

How Does an LED Printer Work?

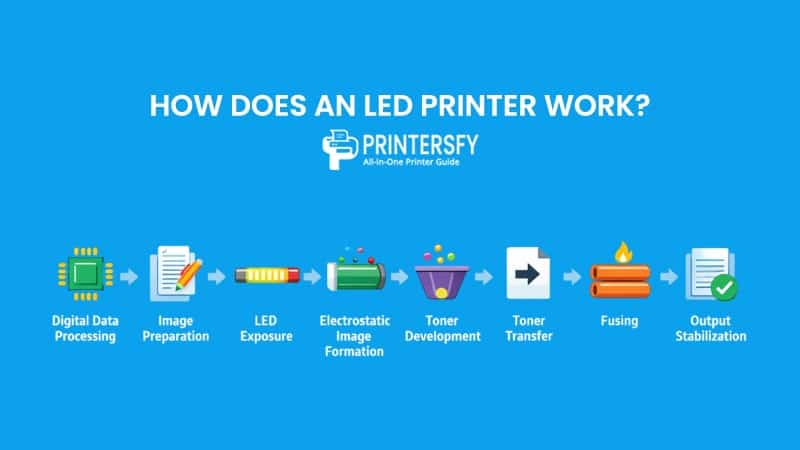

An LED printer operates through a sequence of controlled stages that convert digital data into a physical image. The process is driven by coordination and timing rather than motion-based scanning.

Each stage prepares the conditions for the next, allowing image formation to remain consistent from page to page.

When a print job is received, the printer does not immediately interact with paper or toner. The first phase occurs entirely in the digital domain.

Incoming data is interpreted, structured, and prepared for exposure. Only after this preparation is complete does physical image formation begin.

Digital Image Processing and Print Preparation

When a document is received, the printer converts the information into a raster image composed of precise dot patterns. Each dot represents a location where toner will later be applied or left absent.

This stage determines resolution, edge definition, and overall image structure before any physical printing occurs.

During preparation, the system also calculates margins, scaling, and alignment. The digital image is mapped precisely to the printable area of the page.

Any error at this stage would affect the entire print cycle, which is why image preparation is treated as a controlled and isolated process.

Once finalized, the image data serves as a fixed exposure map. All subsequent stages follow this map without further interpretation.

LED Exposure and Image Formation Across the Page

After preparation, the exposure stage begins. A stationary line of LEDs activates according to the image data, selectively discharging areas on the charged imaging surface.

Each diode corresponds to a specific horizontal position, allowing exposure to occur simultaneously across the printable width.

This LED array method creates an invisible electrostatic image beneath the surface. Because the LEDs remain fixed, exposure timing stays consistent across print cycles.

With no scanning motion involved, alignment and spacing are determined entirely by the physical LED arrangement and digital control, reducing variability during image formation.

Electrostatic Charging and Toner Development

After exposure, the latent image exists as a pattern of electrical charges. Areas affected by light exposure differ electrically from those that remain charged.

Charged toner particles respond to this pattern and adhere only to the intended image areas. This transforms the invisible electrostatic image into a visible toner pattern.

The accuracy of this stage depends heavily on exposure consistency. Uneven charging would result in density variation or edge irregularities.

At this point, the image is visible but not permanent. The toner rests loosely on the surface and must be stabilized.

Toner Transfer, Fusing, and Output Stabilization

The developed image is transferred from the imaging surface onto paper using electrical forces. This transfer must occur evenly to preserve sharpness and tonal balance.

Once on paper, heat and pressure are applied to fuse the toner. The particles melt and bond with the paper fibers, creating a durable printed image.

Temperature and pressure are carefully controlled to avoid distortion, smearing, or surface damage.

By the time the page exits the printer, the image has been fully stabilized. Any inconsistency earlier in the process would be visible at this stage.

How Process Design Influences Print Consistency

The overall workflow in an LED-based system is designed to minimize variation. Fixed exposure and digital control ensure that each page follows the same conditions.

By prioritizing synchronized stages over mechanical movement, LED printing maintains uniform output across long print runs. This stability explains its continued use in professional and office environments.

Summary LED Printer Workflow: Step-by-Step Process

| Workflow Stage | What Happens | Practical Purpose |

|---|---|---|

| Digital Data Processing | The printer converts incoming documents into a rasterized image, defining dot placement, resolution, and page layout. | Ensures the digital file is precisely mapped before any physical printing begins. |

| Image Preparation | The processed image data is aligned with the printable area, including margins and scaling. | Prevents misalignment and maintains consistent positioning across pages. |

| LED Exposure | A fixed array of LEDs activates according to the image data, exposing the charged surface simultaneously across the page width. | Creates a uniform electrostatic image without relying on mechanical scanning. |

| Electrostatic Image Formation | Exposed areas alter their electrical charge, forming an invisible latent image. | Establishes the pattern that determines where toner will adhere. |

| Toner Development | Charged toner particles are attracted to the exposed areas of the latent image. | Turns the invisible electrostatic pattern into a visible toner image. |

| Toner Transfer | Electrical forces transfer the toner image from the imaging surface onto paper. | Moves the image accurately while preserving detail and density. |

| Fusing | Heat and pressure permanently bond the toner to the paper fibers. | Produces a durable, smudge-resistant printed page. |

| Output Stabilization | The finished page cools and exits the printer. | Ensures the final output remains stable and consistent. |

Core Components of an LED Printer

An LED printer is built around a set of components designed to work together with minimal mechanical complexity. Each this printer part plays a defined role within the printing process and does not operate in isolation.

The overall print engine architecture is intentionally structured to keep movement predictable, exposure stable, and output consistent over time. Examining these components individually helps clarify how the system maintains accuracy while limiting unnecessary mechanical stress.

LED Array Exposure System

At the center of the system is the LED array exposure unit. It consists of a fixed line of light-emitting diodes positioned across the printable width. Each diode corresponds to a precise horizontal position on the page and activates only when required by the image data.

Because the array remains stationary, exposure does not rely on scanning motion. This reduces alignment variability and removes a common source of mechanical inconsistency.

The LED print head operates with precise timing control. When activated, individual diodes emit light that alters the electrical charge on the photoconductive surface beneath, forming the latent image.

Since the exposure system is fixed in place, the distance between the light source and the imaging surface remains constant. This consistency contributes directly to uniform image formation across print cycles.

Imaging Drum and Photoconductive Surface

The imaging drum is the surface where the image first takes physical form. It is coated with a photoconductive material that reacts to light and electrical charge.

Before exposure, the drum is uniformly charged. This creates a stable baseline condition for image development.

As the LED array activates, exposed areas on the drum change their electrical properties. These changes define the invisible image pattern that will later attract toner.

The accuracy of this stage depends on charge uniformity and surface consistency. In an LED-based system, the fixed exposure distance helps ensure even light distribution, reducing variations that could affect density or clarity.

Toner and Developer Unit

Once the latent image exists on the drum, the toner and developer unit becomes active. Toner particles carry an electrical charge that causes them to adhere only to specific areas defined by the image pattern.

The developer mechanism regulates toner delivery, ensuring even distribution and controlled interaction with the charged surface.

This stage largely determines edge sharpness and tonal consistency. Excess toner can cause blurring, while insufficient toner leads to faint output.

Because exposure remains stable, toner behavior is more predictable. This simplifies calibration and reduces the likelihood of uneven print density across multiple pages.

Transfer Belt or Roller Mechanism

After toner development, the image must be transferred from the drum onto paper. This is handled by a transfer belt or roller system that uses electrical forces to guide toner particles accurately.

The primary objective at this stage is precision rather than speed. Any misalignment would distort the final image.

In LED-based print engines, the transfer stage is designed to maintain consistent pressure and electrical conditions. This helps preserve fine details and reduces toner scattering inside the device over time.

Fusing Assembly

The fusing assembly is responsible for making the image permanent. After toner is transferred, heat and pressure are applied to melt the toner particles and bond them to the paper fibers.

This process must be carefully controlled to avoid smearing, deformation, or surface damage.

In an LED printer, the fusing stage is calibrated to work in balance with the toner formulation and paper path. Stable temperature and pressure ensure durable, smudge-resistant output.

The reliability of this stage plays a major role in long-term print quality, particularly in high-volume environments.

Controller Board, Firmware, and Image Logic

The final core component is the controller board and its associated firmware. This system manages data processing, exposure timing, and coordination across the entire print cycle.

Incoming digital files are translated into precise instructions that control LED activation, toner application, and paper movement.

The firmware acts as the decision-making layer of the system. It ensures that all components operate in sync, maintaining consistent results from one job to the next.

Firmware updates can also improve efficiency, compatibility, and error handling without altering physical hardware. This software-driven control is central to the predictability associated with LED printing.

Together, these components form a cohesive system. Rather than relying on complex motion or constant adjustment, consistency is achieved through fixed exposure, controlled charge behavior, and coordinated process logic.

Key Features of LED Printers

The defining features of LED-based printers are closely tied to how the technology approaches image exposure and mechanical design. Instead of relying on movement during exposure, the system uses fixed, digitally controlled light sources within a simplified internal layout.

These design choices influence long-term behavior, output consistency, and suitability for professional environments where reliability outweighs visual novelty.

Fixed Exposure and Mechanical Simplicity

One of the most important characteristics is the fixed exposure system. Because the light source does not move during image formation, exposure depends on digital timing rather than mechanical precision.

This removes a layer of complexity that would otherwise require frequent alignment and calibration.

With fewer moving parts involved in exposure, mechanical wear is reduced. Long-term performance becomes more predictable, and gradual drift is less likely to affect output quality.

Compact Print Engine Design

The simplified exposure architecture also enables a more compact print engine. By eliminating components associated with moving light systems, manufacturers can reduce the internal footprint of the device.

This allows for smaller designs without sacrificing core functionality.

Independent analysis from :contentReference[oaicite:0]{index=0} has noted that LED-based printers often achieve a compact form factor due to their simplified exposure systems.

A smaller internal layout also improves efficiency. Shorter mechanical paths reduce opportunities for misalignment, vibration, and internal wear during operation.

Uniform Page-Wide Exposure

Uniform exposure across the page is another defining feature. Because the LED array spans the printable width, exposure occurs simultaneously rather than sequentially.

Each area of the page receives light under the same conditions. This helps maintain consistent density from edge to edge.

Over time, this page-wide exposure reduces subtle variations that can occur in motion-based systems, supporting stable output across repeated print jobs.

Predictable Print Behavior Over Time

Taken together, these characteristics result in predictable print behavior. An LED-based printer is designed to perform consistently over months of use, assuming normal maintenance.

The combination of fixed exposure, compact engine design, and reduced mechanical dependency minimizes gradual performance changes.

For office and professional users, this predictability is often more valuable than peak performance specifications.

Core Technical Features of LED Printers

| Feature | Technical Description | Practical Impact |

|---|---|---|

| LED Array | Fixed page-wide exposure | Uniform imaging |

| Mechanical Design | Minimal moving parts | Lower wear |

| Exposure Method | Simultaneous illumination | Consistent output |

| Engine Size | Compact architecture | Space efficiency |

Advantages of LED Printers

The advantages of LED printers come directly from the design principles that define the technology. By prioritizing stability, simplified mechanics, and controlled exposure, an LED-based system delivers benefits that become more apparent over long-term use.

These strengths are especially relevant in office and professional environments, where consistency and reliability matter more than short-term performance demonstrations.

Reduced Mechanical Complexity

A primary advantage is reduced mechanical complexity. Because image exposure does not rely on moving components, fewer parts are subject to continuous mechanical stress.

This lowers the risk of wear-related issues and reduces the need for frequent realignment. Over time, this leads to steadier operation and fewer interruptions caused by mechanical faults.

Long-Term Reliability Characteristics

Reliability is measured over thousands of printed pages rather than individual jobs. LED printers are designed with this long-term perspective in mind.

Their simplified internal structure supports stable performance as usage increases. This makes them suitable for environments where printers are expected to operate continuously with minimal supervision.

Consistent Print Output

Consistency is another significant benefit. Once properly calibrated, an LED-based printer tends to maintain stable output characteristics over extended periods.

Text sharpness, image density, and alignment remain uniform across print runs. This reliability is especially valuable in document-heavy workflows where visual variation can create quality concerns.

Operational and Energy Considerations

Operational efficiency is influenced by design simplicity. With fewer moving parts and digitally controlled exposure, the printer can operate without constant mechanical adjustment.

Energy consumption varies by model, but the streamlined exposure process supports stable power usage during normal operation. Together, these factors make LED printers a practical choice for users who value durability, predictability, and controlled output over time.

Limitations of LED Printers

While LED printers offer clear strengths in stability and mechanical simplicity, they also come with practical constraints that should be understood before choosing the technology.

These limitations are not execution flaws, but trade-offs resulting from how LED printing is designed and positioned. Recognizing these constraints helps set realistic expectations, particularly for professional users evaluating long-term suitability.

Limited Market Availability

One of the most noticeable limitations is market availability. Compared to more widely adopted printing technologies, LED printers are produced by a smaller number of manufacturers and offered in fewer models.

This narrower selection reduces choice in areas such as speed, size, or specialized features. Availability can also vary by region, making it more difficult to standardize on a single model across multiple locations.

Limited exposure in the consumer market also affects familiarity. Many users encounter LED printers only in specific office or business settings, reinforcing the perception that the technology is niche rather than mainstream.

Scalability and Product Range Constraints

Scalability is another consideration. LED printers are commonly designed for defined workload ranges, often centered on small to medium office environments.

While they handle consistent document printing well, options become more limited at very high volume levels or in highly specialized configurations.

This does not mean LED-based systems cannot scale, but the product range typically emphasizes reliability and consistency over extreme flexibility. Organizations with rapidly changing requirements may therefore find fewer suitable options.

Color Precision Limitations

Color handling can also be a constraint depending on the application. LED printing prioritizes uniform exposure and predictable output, which benefits text and standard graphics.

For color-critical work requiring fine tonal variation or advanced color management, some LED printers may feel restrictive. This reflects the design focus of the technology rather than a universal limitation across all models.

Specialized Maintenance Factors

Although LED printers are associated with reduced mechanical wear, maintenance can still involve specialized parts or expertise.

Because fewer vendors support the technology, sourcing replacement components or service support may take longer in some regions. For organizations that depend on rapid on-site servicing, this can be a practical drawback.

Practical Use Cases for LED Printers

Despite these limitations, LED printers remain well suited to specific environments where consistency and predictability are prioritized over variety.

Understanding common use cases helps clarify when the technology is an effective fit rather than a compromise.

Office and Business Environments

LED printers are frequently used in offices where documents are produced daily and visual consistency is important.

Administrative departments, shared workspaces, and internal print rooms benefit from stable output and low variation. Once configured, the printer tends to behave predictably, reducing the need for constant adjustment.

Professional Document Printing

LED-based systems are also common in professional document production, including reports, contracts, manuals, and internal publications.

These materials prioritize clarity, alignment, and repeatability over complex color effects. Uniform exposure and controlled print behavior support clean and reliable results in these contexts.

When LED Printing Is the Right Choice

LED printing is most appropriate when long-term stability outweighs the need for extensive customization.

Organizations that value predictable performance, controlled output quality, and mechanical simplicity often find the technology dependable. When printing demands are consistent and well defined, LED-based systems align closely with practical requirements.

Longevity, Maintenance, and Operational Characteristics

Long-term behavior is where LED printers tend to demonstrate their real value. Beyond initial setup and early output quality, how a device ages under regular use is equally important.

LED printing is built around controlled exposure and reduced mechanical dependence. These design choices directly influence durability, maintenance patterns, and day-to-day operation over time.

Component Wear and Durability

Component wear in LED-based systems is generally more predictable than in printers that rely heavily on moving exposure mechanisms.

Because exposure is fixed and electronically controlled, fewer parts experience constant motion during each print cycle. This reduces alignment drift and minimizes stress on precision components.

Wear still occurs in areas such as paper handling, toner interaction, and heat application. However, it tends to follow a steady and expected pattern, supporting stable performance across large print volumes.

Maintenance Philosophy of LED Printers

Maintenance is less about frequent adjustment and more about periodic servicing.

Routine tasks focus on cleaning, consumable replacement, and ensuring electrical and thermal conditions remain within specification. There is typically less need for recalibration related to exposure alignment.

This maintenance approach suits environments where printers are expected to operate reliably with minimal intervention, even if specialized parts are occasionally required.

Expected Lifecycle in Professional Use

In professional settings, LED printers are often expected to remain in service for many years.

When used within intended workload ranges and maintained properly, the technology supports a long operational lifespan. Consistent exposure behavior and controlled wear allow performance to decline gradually rather than unpredictably.

For organizations that prioritize dependable output over time, this lifecycle behavior represents a meaningful advantage.

LED Printer vs Other Toner-Based Printers

Toner-based printers share the same fundamental objective: producing durable, fast-drying output suitable for everyday use.

While these devices rely on similar electrophotographic principles, differences emerge in how images are exposed and controlled. An LED-based system follows the same core process as laser printers, but its exposure method leads to distinct behavior in long-term operation.

vs Monochrome Laser Printer

When compared with monochrome laser printers, LED-based printers use a more static exposure approach.

Laser printers rely on a moving beam that scans across the imaging surface. In contrast, LED systems expose the page using a fixed array of light-emitting diodes.

In daily office use, both technologies produce sharp text and clean documents. For standard workloads, visible output quality is often comparable.

Differences become more noticeable over time. Because LED exposure does not involve scanning motion, alignment tends to remain stable across extended use.

Monochrome laser printers depend more heavily on precise mechanical movement. As components wear, periodic adjustment may be required to maintain exposure accuracy.

For environments focused on steady document production rather than frequent configuration changes, the LED printer approach often feels more predictable.

vs Color Laser Printer

Color laser printers introduce additional complexity by managing multiple color channels.

This added control supports broader color flexibility and advanced management options, but it also increases calibration and mechanical demands.

Color-capable LED printers still rely on fixed exposure, which can simplify alignment between color layers.

However, color-focused models remain more specialized overall, regardless of whether exposure is handled by lasers or LED arrays.

In practical terms, color laser printers are often selected for visual variety and detailed color control.

LED-based systems emphasize uniformity and long-term stability. The choice depends less on raw print quality and more on how much complexity and ongoing adjustment a user is willing to manage.

Final Perspective on LED Printer Technology

An LED printer represents a deliberate approach to digital printing rather than an experimental alternative.

Its design prioritizes stability, consistency, and controlled operation over mechanical complexity.

By relying on fixed exposure and synchronized processes, the technology focuses on reliable output across repeated use rather than extensive customization.

From an engineering standpoint, LED printing is built on clear technical principles.

Exposure behavior is predictable, component interaction is controlled, and performance characteristics remain stable as usage increases.

These qualities make the technology especially relevant in professional and office environments where consistency outweighs novelty.

Viewed as a complete system, LED printing fills a specific role within the broader printing landscape.

It is not intended to replace every other toner-based technology, nor does it attempt to do so.

Instead, it offers dependable performance, manageable maintenance, and long-term operational stability.

For users who value these characteristics, LED printers remain a practical and well-considered choice.

FAQs About LED Printers

Do LED printers use toner?

Yes. An LED printer is a toner-based device. It uses powdered toner that is applied to paper through an electrophotographic process and fixed with heat.

Are LED printers reliable?

In general, yes. LED printers are known for stable operation because their exposure system has fewer moving parts, which helps reduce mechanical wear over time.

How do LED printers work?

They form images by using a fixed array of LEDs to expose a charged surface. Toner adheres to the exposed areas, is transferred to paper, and then fused permanently with heat.

Is an LED printer a non-impact printer?

Yes. LED printers are non-impact printers because they create images using light, electrical charge, and toner rather than physical contact.

Which is better, LED or laser?

Neither is universally better. The choice depends on workload, maintenance preferences, and consistency requirements rather than raw print quality alone.