A large Format Printer has become a quiet constant in environments where communication must occupy physical space rather than screens. Retail interiors, transit hubs, exhibitions, and construction sites all rely on visuals that scale with architecture and movement. In these settings, printing is less about documents and more about presence, durability, and legibility across distance.

Large format printing evolved as businesses and institutions needed output that could integrate with walls, glass, vehicles, and temporary structures. Wide format printing supports campaigns and information systems designed for ambient light and varied viewing angles, while large scale printing answers the need for consistency across repeated installations and long production runs.

Market data shows this shift is structural, not incidental. According to Grand View Research, the global large Format Printer market was valued at USD 9.11 billion in 2023 and is projected to reach USD 12.70 billion by 2030, growing at a CAGR of 5.0%. As visual communication continues to expand outward, the large Format Printer functions as industrial infrastructure for modern visual production.

This context explains why investment, workflow redesign, and material experimentation increasingly revolve around scale, reliability, and integration with physical environments rather than traditional page-based output.

What Is a Large Format Printer

At the core, a large Format Printer is defined by the width of media it can reliably support and the contexts in which that capability is required. According to professional printing industry references, large Format Printer systems are generally defined as devices capable of printing widths ranging from approximately 18 inches up to more than 100 inches. This range marks the point where standard sheet-based printing becomes inefficient or impractical.

Within this scope, large format systems are commonly used for signage, technical drawings, decorative panels, and display graphics. This printer type is expected to manage continuous media, maintain alignment over distance, and deliver output intended for installation rather than filing or binding.

Large Format vs Standard Printers

The distinction between large format and standard printers is primarily conceptual. Standard printers assume close viewing, short output cycles, and frequent handling. Their success is measured by convenience and document clarity at arm’s length.

A large Format Printer, by contrast, operates under assumptions of distance, exposure, and physical integration. Output is designed to be seen from across rooms or streets, interact with architectural surfaces, and remain stable after installation. This difference in intent defines the category more clearly than any single specification.

How Large Format Printer Work

A large Format Printer operates within a production environment where output length, material behavior, and mechanical stability must remain predictable over time. Printing at this scale is not treated as a sequence of isolated pages, but as a continuous physical operation that unfolds across meters of media. Each stage influences the next, and small inconsistencies tend to amplify rather than reset during the run.

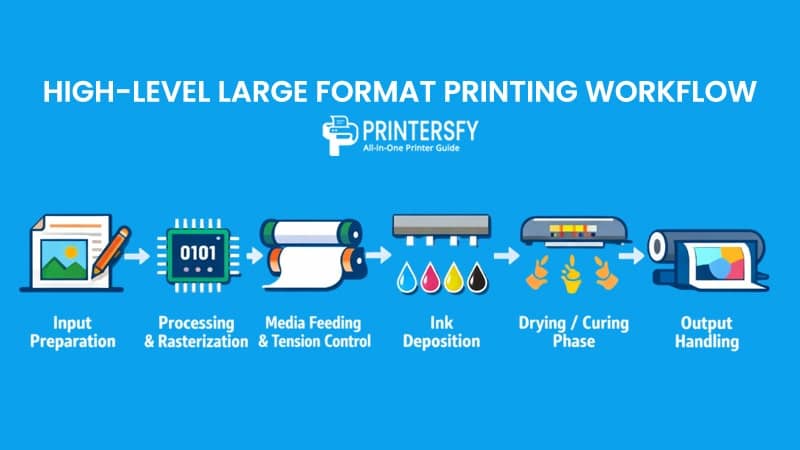

Workflow Stage What Happens Why It Matters at Large Scale Input Preparation Full-scale digital files are prepared to match final installation size, including resolution, bleed, and layout alignment. Errors at this stage multiply across meters of output and cannot be corrected mid-run. Processing & Rasterization Software converts design data into coordinated instructions for carriage movement, ink firing, and media advance. Timing precision replaces page-by-page correction, making synchronization critical. Media Feeding & Tension Control Roll or rigid media is advanced continuously while tension systems keep it flat and aligned. Even minor shifts accumulate distortion over long print lengths. Ink Deposition Ink is applied in controlled, overlapping passes with consistent spacing and pressure. Uniform ink behavior prevents color drift and banding across wide surfaces. Drying / Curing Phase Printed media passes through drying zones, heaters, or curing modules depending on ink technology. Stabilizes output before handling, preventing smearing or deformation. Output Handling Finished prints are guided to take-up reels, collection tables, or rigid output beds. Maintains physical integrity of long or heavy prints after production.

High-Level Printing Workflow

The workflow begins with full-scale digital files prepared to match final installation dimensions. Processing software translates visual data into coordinated instructions that govern carriage motion, ink release, and media advance. Unlike small printers that pause between sheets, a large Format Printer maintains uninterrupted movement once printing starts, relying on timing accuracy rather than repetition to preserve alignment.

As media progresses through the system, ink is applied in controlled passes that overlap with precise spacing. Output handling is part of the workflow rather than an afterthought, involving drying zones, curing modules, or take-up reels that stabilize the print before it is removed from the machine. This continuity defines how the wide format printing process sustains visual coherence over long distances.

Ink Delivery and Media Handling Principles

Ink delivery must remain consistent across wide spans and extended operation periods. A large Format Printer regulates pressure, temperature, and nozzle performance so that color density does not drift as the run progresses. At the same time, roll media printing introduces tension variables that require constant correction to keep substrates flat and evenly positioned beneath the printheads.

Media handling systems operate in parallel with ink delivery. Rollers, guides, and vacuum zones counteract curl and gravity while allowing continuous advance. If material shifts even slightly, distortion accumulates across the output length. For this reason, mechanical control is treated as a core printing function rather than a supporting mechanism.

Why Scale Changes the Printing Process

Scale alters how quality is perceived and how errors emerge. Variations that remain invisible on small prints become immediately noticeable when expanded across large surfaces. A large Format Printer is therefore engineered to prioritize stability, environmental control, and repeatability. Printing at scale becomes a managed system shaped by physics and material behavior, not merely a larger version of standard output.

Types of Large Format Printer by Technology

Large-scale printing environments rely on different technologies depending on durability needs, media type, and production rhythm. A large Format Printer is not defined by a single method, but by a family of printing technologies that address distinct industrial and creative requirements. Each technology reflects trade-offs between ink chemistry, curing method, surface compatibility, and operational complexity.

Understanding these technologies clarifies why no single large Format Printer configuration dominates all use cases. Instead, production decisions are shaped by where output will be installed, how long it must last, and how tightly it must integrate with surrounding materials.

Solvent Inkjet Printers

Solvent inkjet printers use inks formulated with aggressive solvents that partially dissolve the surface of the printing media. As ink is deposited, pigments penetrate into the substrate rather than sitting on top, creating strong adhesion once the solvent evaporates. This process allows the large Format Printer to produce output suitable for outdoor exposure and flexible materials.

Because solvent inks require evaporation time, printing speed is balanced against drying capacity. Heating elements and airflow systems are often integrated to stabilize output before handling.

The primary strength of solvent systems lies in durability. Prints resist moisture, UV light, and abrasion without additional lamination in many applications. This makes solvent inkjet printers common in signage and vehicle graphics.

Trade-offs include longer drying times, odor management, and environmental considerations. Ventilation and material compatibility must be carefully managed within the production space.

Aqueous Inkjet Printers

Aqueous inkjet printers rely on water-based inks that carry dye or pigment particles. These inks sit closer to the surface of the media, producing high color accuracy and smooth gradients. In a large Format Printer using aqueous inks, image quality often takes priority over environmental resistance.

Because water must evaporate, these systems typically operate in controlled indoor environments with coated papers or specialty media.

Aqueous systems are widely used for photographic prints, fine art reproduction, and indoor display graphics. Their strength lies in visual fidelity rather than durability, making them less suitable for prolonged outdoor exposure without protection.

Latex Inkjet Printers

Latex inkjet printers use water-based inks combined with polymer particles that form a film when heat is applied. During printing, integrated heaters cure the ink almost immediately. This allows a large Format Printer to deliver dry, ready-to-finish output directly from the machine.

Instant curing shortens production cycles and simplifies handling, especially in fast-paced commercial environments.

Latex inks emit minimal odor and do not require solvent ventilation systems. This makes them suitable for shared or enclosed workspaces. Energy consumption during curing, however, becomes a factor in operational planning.

UV-Cured Large Format Printer

UV-cured systems use inks that harden instantly when exposed to ultraviolet light. A large Format Printer with UV curing can print directly onto rigid boards, plastics, glass, and metals as well as flexible materials. Ink remains on the surface, forming a durable layer once cured.

This instant curing eliminates drying time and allows precise layer control, including textured effects.

UV-cured output offers excellent scratch resistance and color stability. However, the rigid ink layer may crack on highly flexible substrates. Equipment cost and maintenance complexity are also higher compared to other technologies.

Dye-Sublimation Printers

Dye-sublimation printing uses heat to convert solid dye into gas, which then bonds with polyester fibers or coated substrates. In this process, a large Format Printer first prints onto transfer paper before heat pressing completes the image.

The result is coloration embedded within the material rather than applied on top.

This technology is dominant in textile graphics, soft signage, and fabric displays. Colors remain vibrant, washable, and resistant to cracking, making dye-sublimation ideal for applications involving movement or folding.

Plotter / Pen-Based Systems

Plotters use pens or technical instruments to draw vector lines directly onto media. Historically, these systems defined precision output for engineering and architectural documentation before inkjet dominance. Early large Format Printer systems in technical fields often relied on this approach.

While pen plotters are largely replaced by inkjet systems, the term “plotter” persists. It now describes large format devices used for CAD drawings, reflecting functional lineage rather than mechanical method.

Comparison of Large Format Printing Technologies

| Technology | Ink Type | Typical Media | Key Strength | Main Limitation |

|---|---|---|---|---|

| Solvent Inkjet | Solvent-based | Vinyl, banner | Outdoor durability | Odor, drying time |

| Aqueous Inkjet | Water-based | Photo paper | Color accuracy | Low weather resistance |

| Latex Inkjet | Polymer-based | Mixed media | Fast turnaround | Energy use |

| UV-Cured | UV-reactive | Rigid & flexible | Surface versatility | Higher cost |

| Dye-Sublimation | Dye gas transfer | Textiles | Embedded color | Limited substrates |

| Plotter Systems | Pen-based | Technical paper | Line precision | Obsolete for graphics |

Types of Large Format Printer by Physical Mechanism

While printing technologies explain how ink is formed, cured, or bonded to different surfaces, they do not fully describe how large format systems physically interact with media during production. These distinctions emerge from mechanical design choices that determine how materials are supported, moved, and stabilized as printing takes place across varying formats and workflows.

Flatbed Printers

Flatbed printers are built around a stationary printing surface where media remains fixed while the carriage moves above it. This physical design allows a large Format Printer to work directly with rigid media such as boards, acrylic, wood panels, and metal sheets. Because the substrate does not bend or advance during printing, positional accuracy becomes easier to maintain across wide surfaces.

Rigid media handling changes how production is planned. Materials are loaded individually rather than fed continuously, which slows throughput but increases control. A large Format Printer using a flatbed mechanism is often chosen when alignment, edge definition, or material thickness matters more than speed.

From a production perspective, flatbed systems support direct-to-substrate workflows. This removes the need for mounting or lamination after printing, but requires more floor space and careful handling of heavy materials during loading and unloading.

Roll-to-Roll Printers

Roll-to-roll printers are designed around continuous media movement. Flexible materials such as vinyl, film, fabric, and banner stock are fed from a roll, printed, and collected on a take-up system. In this configuration, a large Format Printer prioritizes efficiency and consistency across long runs.

Continuous media workflow enables higher productivity, especially for signage and display graphics. Tension control, tracking accuracy, and drying or curing zones work together to keep output aligned over extended lengths. These systems are optimized for repetition rather than individual placement precision.

Hybrid Printers

Hybrid printers combine flatbed and roll-to-roll capabilities within a single machine. A large Format Printer with a hybrid mechanism can switch between rigid sheets and flexible rolls, allowing shops to handle diverse jobs without dedicated equipment.

This flexibility comes with operational compromise. Hybrid systems rarely match the maximum speed of roll-only printers or the handling strength of dedicated flatbeds. However, for environments with varied media requirements, the combined capability simplifies workflow planning and space usage.

Physical Mechanisms and Media Compatibility

| Mechanism Type | Media Form | Typical Use Context |

|---|---|---|

| Flatbed | Rigid sheets | Boards, panels, signage |

| Roll-to-Roll | Flexible rolls | Banners, vinyl graphics |

| Hybrid | Rigid & flexible | Mixed production workflows |

Key Features of Large Format Printer

While physical mechanisms define how large format systems move and support media, they do not explain how output quality, consistency, and scalability are sustained across different production environments. These aspects emerge from a separate layer of design considerations that shape how a printer performs once media is in motion and ink is in use.

Media Width and Handling Systems

Media width capability defines the physical limits of a large Format Printer. Wider systems accommodate fewer seams and larger visuals, but require stronger frames, more precise tracking, and advanced handling components to keep substrates stable throughout printing.

Media handling systems manage alignment, tension, and flatness. Rollers, vacuum tables, and edge guides ensure predictable movement, especially as print length increases. These features directly influence output accuracy more than headline resolution figures.

Ink Systems and Color Consistency

Ink systems are engineered to deliver consistent color over long production cycles. A large Format Printer must maintain pressure, temperature, and nozzle performance so that visual output does not drift as printing progresses.

Color consistency is also shaped by profiling and calibration routines. These processes ensure that output remains stable across different media types and repeat jobs, reinforcing predictability in professional environments.

Print Speed and Scalability

Print speed influences how scalable a system is in real-world production. A large Format Printer designed for high throughput balances carriage speed with drying or curing capacity to avoid bottlenecks during long runs.

Scalability is less about maximum speed and more about sustained performance. Machines optimized for continuous operation reduce downtime and maintain quality across large job volumes.

Viewing Distance vs Output Detail

Output detail must be evaluated in relation to viewing distance. A large Format Printer producing graphics meant to be seen from afar prioritizes uniform color and edge clarity over extremely fine detail.

This relationship shapes design decisions and printer selection alike. Understanding how viewers interact with large visuals helps align technical capability with practical perception.

Advantages & Limitations of Large Format Printer

Once large-scale systems move beyond technical specifications and into daily operation, their strengths and constraints become clearer through use. Performance is no longer judged by size alone, but by how reliably output can be produced, adapted, and maintained across different environments. In this context, a large Format Printer reveals its value through a balance of visual power and operational discipline.

Advantages

The most apparent advantage is visual impact. Large-format output commands attention by occupying physical space in a way smaller prints cannot. Scale allows information to remain legible from distance and visible within complex visual surroundings, making communication more immediate and authoritative.

Key advantages commonly include:

- Visual presence at scale, enabling graphics to interact with architecture, movement, and viewing distance

- Consistent readability, even in environments with competing visual elements

- Stronger brand reinforcement, as repeated large visuals create spatial familiarity

Versatility further strengthens the case. A large Format Printer supports a wide range of materials and output types, allowing the same system to serve multiple industries and applications without redesigning the entire workflow.

Additional advantages related to versatility and scalability:

- Media flexibility, from flexible rolls to rigid substrates

- Adaptability across use cases, including signage, technical output, and decorative graphics

- Scalable production, where established workflows can expand in volume without sacrificing consistency

Together, these advantages explain why large format systems are often positioned as long-term infrastructure rather than task-specific tools.

Limitations

Despite its strengths, large format printing introduces constraints that must be managed deliberately. Cost considerations represent the most significant limitation. Equipment investment, consumables, energy usage, and maintenance increase alongside output size, making efficiency and planning essential.

Common limitations include:

- Higher initial and operational costs, especially compared to standard printing systems

- Ongoing consumable expenses, including ink, media, and replacement components

- Energy demands, particularly for curing, drying, or climate control

Space and maintenance further shape feasibility. A large Format Printer requires sufficient floor area, controlled environmental conditions, and regular calibration to maintain output quality over time.

Operational limitations related to space and upkeep:

- Dedicated production space, including material staging and handling areas

- Routine maintenance requirements, which directly affect reliability

- Environmental sensitivity, where temperature and humidity influence results

These limitations do not negate the value of large format systems, but they do frame them as production assets that reward planning and discipline rather than casual use.

Uses / Real-World Applications

As large-scale output becomes part of physical environments, its applications follow practical demands rather than experimentation. Large format printing is used where visibility, proportion, and durability shape how information is experienced. In these contexts, a large Format Printer functions as a production tool that aligns visual intent with real-world conditions.

Advertising and Visual Signage

Advertising remains the most common use case. Large visuals are designed to compete within crowded environments where attention is limited and viewing time is brief. Signage must remain readable from distance, maintain color consistency across locations, and withstand environmental exposure.

Common uses include:

- Outdoor and indoor signage, such as banners, posters, and billboards

- Retail displays, including window graphics and in-store promotions

- Event and exhibition graphics, where scale supports wayfinding and branding

In signage printing, scale ensures messages retain clarity even when viewed in motion or from across large spaces.

Architecture, Engineering, and CAD Drawings

In technical fields, output accuracy matters more than visual impact. Architecture, engineering, and construction rely on full-scale drawings that preserve dimensions and line precision. CAD printing allows plans to be read, annotated, and referenced on-site without reduction.

Typical applications include:

- Construction plans and blueprints

- Site layouts and technical schematics

- Infrastructure and utility drawings

Here, a large Format Printer supports functional communication, ensuring designs translate reliably from screen to physical workspace.

Photography and Fine Art Printing

Photography and fine art use scale to alter viewer engagement. Large prints emphasize texture, tonal transitions, and material presence, encouraging longer interaction compared to small-format output.

Use cases often involve:

- Gallery and exhibition prints

- Limited-edition photographic works

- Decorative interior installations

In these settings, print quality and material choice are prioritized over speed, shaping how images are perceived at scale.

Textile and Soft Signage Production

Textile printing introduces flexibility and movement into large visuals. Fabric-based graphics are lighter, easier to transport, and adaptable to temporary installations. Soft signage is commonly used where rigid materials would be impractical.

Applications include:

- Fabric backdrops and banners

- Trade show displays and stage graphics

- Interior decorative textiles

Textile printing allows a large Format Printer to support environments that require portability without sacrificing visual continuity.

Industrial and Prototyping Contexts

Industrial applications focus on function rather than presentation. Large-format output is used to prototype layouts, test form factors, and create instructional visuals that match real dimensions.

Typical uses include:

- Templates and mock-ups

- Process diagrams and safety graphics

- Pre-production layout testing

In these contexts, scale bridges the gap between design intent and physical execution, allowing decisions to be made before final production.

Specialized Printers Within the Large Format Ecosystem

As printing needs become more specific, scale alone no longer defines the right equipment. Many production environments rely on specialized printers that are designed around narrow applications, material constraints, or operational contexts. Within this landscape, a large Format Printer often sits alongside other systems rather than replacing them, forming part of a broader, task-oriented printing ecosystem.

This section serves as a navigational bridge, highlighting how specialization emerges not from size, but from purpose and workflow focus.

Application-Based Specialized Printers

Some printer categories are defined primarily by what they produce and where that output is used. These systems are optimized for repeatability, material compatibility, or installation context rather than general versatility.

- Label printers focus on precision, adhesion, and consistent output on small substrates used for packaging, logistics, and identification.

- Banner printers are tuned for continuous production on flexible media, prioritizing speed and outdoor durability.

- Flex printers support large advertising graphics printed on vinyl or flex materials commonly used in commercial signage.

- Photo printers emphasize color accuracy, tonal smoothness, and surface quality for photographic and display output.

- Textile printers are designed around fabric behavior, supporting soft signage, apparel, and interior décor applications.

Each of these specialized printers addresses a narrow production need that would be inefficient or impractical to handle with a single generalized system.

Technology & Size-Based Specializations

Other printer categories are defined by underlying technology or standardized output dimensions. These systems exist to solve operational problems tied to speed, format consistency, or integration with point-of-use environments.

- Thermal printers rely on heat-based processes for fast, low-maintenance output.

- Receipt printers are optimized for transactional environments where speed and reliability matter more than longevity.

- A3 printers and A2 printers address fixed-format needs in offices, studios, and technical settings where standardized paper sizes are essential.

Together, these categories illustrate how specialization complements large-format production, ensuring that each printing task is handled by systems designed for its specific constraints rather than forcing all output through a single machine.

Wrapping Up

Large-format printing rarely exists in isolation. It sits at the intersection of design intent, physical space, material behavior, and production discipline. What gives this category lasting relevance is not simply the ability to print bigger, but the way scale reshapes how visuals function once they leave the machine and enter real environments.

A large Format Printer becomes meaningful when its output aligns with context—how far it will be viewed, how long it must last, and how it integrates with surrounding surfaces. These considerations explain why large-format systems continue to evolve alongside architecture, retail, manufacturing, and visual communication rather than replacing smaller printers outright. Each format serves a role shaped by use, not hierarchy.

Seen this way, large-format printing is less about excess and more about proportion. It addresses situations where size is not a luxury, but a requirement for clarity, orientation, and presence. Understanding that relationship helps position large-format systems as deliberate production tools rather than oversized alternatives to standard printers.

FAQs About Large Format Printer

How to choose a large format printer?

Selection depends on intended use, media types, installation environment, and production volume. Matching technology and physical mechanism to real workflow needs is more important than maximum size or speed.

What is the lifespan of a large format printer?

With proper maintenance and consistent use, many systems remain operational for several years. Longevity is influenced by workload intensity, environment, and servicing practices.

Can a large format printer print stickers?

Yes, many large-format systems can produce stickers, especially when paired with suitable adhesive media and finishing processes such as lamination and cutting.

How do you maintain a large format printer?

Maintenance typically includes regular cleaning, calibration, environmental control, and timely replacement of consumable components to ensure consistent output quality.

Who uses large Format Printer?

Users range from print service providers and advertising studios to architects, engineers, manufacturers, and organizations that rely on large-scale visual output for communication or production purposes.