Printing technology has evolved far beyond the basic office machines once used only for reports and spreadsheets. As businesses place greater emphasis on visual communication, the expectations for printed output have changed as well. Today, companies need sharper images, consistent colors, and professional presentation to support marketing, branding, and customer engagement. This shift has pushed the graphic printer into a more prominent role within modern printing workflows.

In the past, printers were primarily designed for speed and efficiency, focusing on text-based documents. That approach no longer meets the demands of visually driven industries. From brochures and posters to product packaging and promotional materials, print quality now directly influences how a brand is perceived. A graphic printer addresses these needs by prioritizing visual accuracy, allowing designs created on screen to translate more faithfully into physical form.

Visuals have become a strategic asset in business. Strong branding relies on color consistency, clean graphics, and attention to detail, all of which contribute to credibility and trust. Poorly reproduced prints can weaken a message, while high-quality output reinforces professionalism.

This is why many organizations move beyond standard office devices and adopt specialized printing solutions that can maintain consistent results across different materials and print runs. In this context, the graphic printer supports not only creative work but also long-term brand positioning.

According to industry market research, the global digital printing market continues to grow rapidly due to rising demand for high-quality, on-demand graphic printing solutions.

What Is a Graphic Printer?

A graphic printer is a printing device designed specifically to handle visual-heavy output where detail, color accuracy, and consistency are critical. From a technical standpoint, it operates with higher resolution capabilities, more advanced color management systems, and printing engines optimized for images rather than text alone. These characteristics allow it to reproduce photographs, illustrations, and complex graphics with far greater precision than standard office models.

From a practical perspective, the definition is easier to understand through use. For designers, photographers, and businesses, this type of printer acts as the final bridge between digital files and physical materials. What appears on screen—colors, gradients, textures, and sharp edges—is expected to look the same once printed. This reliability is why many professionals refer to it as a dedicated graphic printing machine, built to deliver predictable and repeatable visual results.

Purpose and Core Function of a Graphic Printer

The main purpose of a graphic printer is to preserve visual integrity throughout the printing process. Instead of prioritizing speed or bulk document output, its core function focuses on reproducing fine details, smooth color transitions, and accurate tones. This makes it especially valuable for work where visual quality directly affects perception, such as branding, marketing, and creative production.

Color accuracy plays a central role in this function. Advanced color processing ensures that prints remain consistent across different runs and media types, reducing unwanted variations. This level of control is essential for businesses that rely on strict brand guidelines or for creatives who need their printed work to match digital designs closely. As a result, these devices are often chosen as a printer for graphic design, where precision matters more than sheer volume.

How a Graphic Printer Differs from Standard Printers

The difference between a graphic printer and a standard printer lies mainly in intent and output quality. Standard printers are built for everyday office tasks such as reports, invoices, and basic graphics. Their design prioritizes affordability and efficiency, which limits how well they handle complex visuals.

In contrast, a graphic printer is engineered with professional output in mind. It supports higher resolutions, broader color ranges, and compatibility with specialty media such as photo paper or thicker stock. These features allow it to produce sharper images, smoother gradients, and more reliable colors over time.

Ultimately, while both types of printers serve important roles, their purposes are distinct. Office printers focus on practicality, while a graphic printer is designed for situations where visual accuracy, presentation, and consistency are essential to the final result.

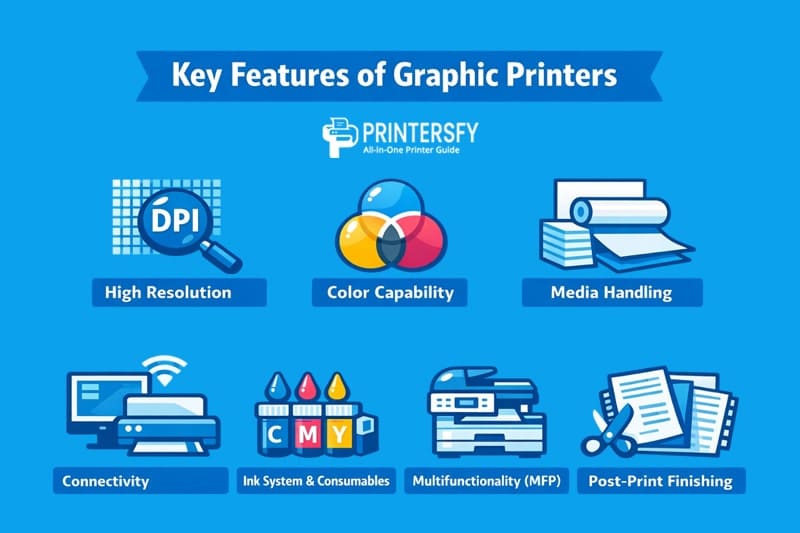

Key Features of Graphic Printers

A graphic printer is defined not by a single specification, but by a combination of technical features that work together to deliver consistent, high-quality visual output. These features are designed to support detailed graphics, accurate color reproduction, and flexible production workflows.

Below are the most important features that distinguish advanced graphic-focused printers from standard office devices.

High Resolution (DPI)

Resolution, measured in dots per inch (DPI), plays a major role in how sharp and detailed printed output appears. Higher DPI allows finer dots to be placed closer together, resulting in smoother edges, clearer text, and more detailed images. This is especially important for photographs, illustrations, and complex designs where small visual elements matter.

In a graphic printer, high resolution ensures that gradients appear smooth rather than banded, and that fine lines or textures remain visible even at close viewing distances. While entry-level models may already offer respectable DPI levels, professional-grade units push resolution further to meet demanding visual standards.

Color Capability and Color Management

Color performance is one of the most critical features in graphic printing. Accurate color reproduction ensures that printed output matches the original design as closely as possible, reducing surprises and reprints.

CMYK vs RGB Printing

Most digital designs are created in RGB color space for screens, while printing relies on CMYK inks. Effective printers manage this conversion carefully so colors remain consistent and visually accurate. Poor handling of this process can lead to dull or unexpected color shifts.

ICC Color Profiles and Color Gamut

Advanced color management uses ICC profiles to standardize how colors are interpreted across devices. A wider color gamut allows more shades to be reproduced, which is essential for brand colors, photography, and marketing materials. Strong color accuracy printing capabilities help maintain consistency across multiple print runs.

Print Technology (Inkjet and Laser)

Print technology directly affects output characteristics, speed, and operating costs. Inkjet systems excel at producing rich colors and smooth gradients, making them ideal for images and creative work. Laser systems, on the other hand, are known for speed and durability, especially in environments with higher volume needs.

When comparing inkjet vs laser printer options, the choice often depends on intended use. A graphic printer may use either technology, but it is optimized to maximize visual quality rather than focusing solely on speed or volume.

Media Handling and Paper Compatibility

Media flexibility is another defining feature. Graphic printing often requires more than standard office paper. Photo paper, thick cardstock, specialty finishes, and large formats all demand precise handling.

A capable media handling printer supports multiple paper sizes, varying thickness levels, and specialty materials without compromising output quality. This flexibility allows creative teams and businesses to experiment with different formats while maintaining consistent results.

Print Speed (PPM)

While speed is not the primary focus in graphic printing, it still affects productivity. Print speed, measured in pages per minute (PPM), influences how efficiently jobs move through a workflow.

In professional environments, balanced performance matters more than raw speed. A graphic printer is designed to maintain output quality even when handling complex files, ensuring that faster printing does not come at the cost of accuracy or detail.

Connectivity and Software Integration

Modern printing workflows rely heavily on digital connectivity. Support for USB, Ethernet, and Wi-Fi enables flexible placement and easy sharing across teams. Seamless integration with design software also reduces friction between creation and production.

Reliable connectivity allows a graphic printer to function as part of a larger workflow, supporting collaboration between designers, marketers, and production teams without constant manual adjustments.

Ink System and Consumables

The ink system influences both output quality and long-term operating costs.

Dye Ink vs Pigment Ink

Dye inks offer vibrant colors and smooth transitions, while pigment inks provide better durability and resistance to fading. The choice depends on whether visual vibrancy or longevity is the priority.

Toner-Based Printing Systems

Toner systems are commonly used in laser printers and are valued for consistency and efficiency in higher-volume environments.

A graphic printer may support different ink or toner systems depending on its intended application, balancing quality with durability.

Multifunctionality (MFP)

Many modern printers combine printing with scanning and copying functions. Multifunctionality supports streamlined workflows, especially in studios or offices where multiple tasks are handled by the same device.

Integrated features reduce the need for separate equipment and help centralize production tasks without sacrificing output quality.

Post-Print Finishing Features

Post-print capabilities enhance the final presentation of printed materials. Finishing options such as precise alignment, edge handling, or compatibility with external finishing equipment contribute to professional results.

For users who need polished output without extensive manual processing, these features add significant value and efficiency.

Key Technical Features of Graphic Printers

| Feature | Entry-Level | Professional |

|---|---|---|

| DPI | 1200–2400 | 2400–4800 |

| Color Management | Basic | Advanced ICC |

| Media Support | Limited | Wide & Thick |

| Ink System | Dye / Toner | Pigment / Advanced |

Taken together, these features explain why a graphic printer is suited for environments where visual accuracy, flexibility, and consistency are essential. Rather than focusing on a single specification, it is the integration of resolution, color control, media support, and workflow connectivity that defines professional-grade graphic printing.

Types of Graphic Printers

Graphic printing covers a wide range of needs, from everyday creative work to highly specialized industrial applications. Because of this, there is no single printer type that fits all use cases. Each category is designed with different priorities, such as color quality, media size, durability, or production volume.

At a high level, printers used for graphic work can be divided into common types and specialized types. Common models are widely used in offices, studios, and small businesses, while specialized printers are designed for specific outputs such as large-format graphics, photographs, or industrial materials. Together, these categories define the modern landscape of the graphic printer market.

Common Types of Graphic Printers

Inkjet Printers

Inkjet technology is one of the most widely used solutions for graphic printing. These printers work by spraying microscopic droplets of ink onto paper, allowing for smooth gradients and rich color reproduction. Because of this capability, inkjet models are often preferred for creative applications such as illustrations, posters, and marketing materials.

An inkjet graphic printer excels at handling images with subtle color transitions and fine detail. It also supports a wide range of media, including photo paper, glossy stock, and specialty surfaces. While ink costs can be higher over time, the visual output makes inkjet printers a popular choice for designers and small print studios that prioritize quality over speed.

Laser Printers

Laser printers use toner and heat-based processes to fuse images onto paper. Traditionally associated with office environments, modern laser models have evolved to handle more complex graphics and higher color accuracy. A laser graphic printer is valued for its speed, durability, and consistency, especially in higher-volume settings.

Laser technology is well suited for businesses that need reliable output with minimal maintenance. While it may not always match inkjet printers in photo realism, it performs well for charts, vector graphics, and branded documents where consistency matters more than subtle gradients.

LED Printers

LED printers operate similarly to laser printers but use light-emitting diodes instead of a laser beam. This design reduces the number of moving parts, which can improve reliability and reduce maintenance requirements. Output quality is comparable to laser systems, making LED printers suitable for graphic-heavy office tasks.

Because of their compact design and stable performance, LED printers are often chosen by businesses that want dependable color output without complex upkeep. They represent a practical option within the broader graphic printer category for organizations that balance quality and efficiency.

Dot Matrix Printers

Dot matrix printers are among the oldest printing technologies still in use today. They create images by striking ink ribbons against paper, resulting in lower resolution compared to modern methods. While not ideal for detailed graphics, they remain relevant in specific industries that require multipart forms or continuous paper.

In graphic printing contexts, dot matrix printers are rarely used for creative work. However, they may still appear in specialized workflows where durability and simplicity outweigh visual quality. Their inclusion highlights how varied the graphic printer landscape can be.

All-in-One / Multifunction Printers

Multifunction printers combine printing, scanning, copying, and sometimes faxing into a single device. For small businesses and studios, this multifunctionality can streamline workflows and reduce equipment clutter.

When designed with strong color handling and resolution, an all-in-one model can serve as an entry-level graphic printer for teams that need versatility alongside moderate visual quality. These devices are best suited for environments where space and budget efficiency are priorities.

Specialized Graphic Printers

Large-Format Printers (Plotters)

Large-format printers, often called plotters, are built to handle oversized media beyond standard paper sizes. They are commonly used for banners, signage, posters, and architectural drawings.

A large format printer is essential in industries such as advertising, construction, and event marketing. These machines emphasize precision over sheer speed, ensuring that large visuals remain sharp and properly scaled. For businesses producing oversized graphics, this type of graphic printer is often indispensable.

Photo Printers

Photo printers are optimized for producing high-quality photographic output. They focus on color depth, tonal accuracy, and smooth transitions, often using specialized ink sets and glossy or luster papers.

Photographers and creative professionals rely on photo printers when image fidelity is critical. While they may not handle high volumes efficiently, their output quality places them among the most visually precise options in the graphic printer spectrum.

Dye-Sublimation Printers

Dye-sublimation printers use heat to transfer dye onto materials, creating images that are embedded rather than layered on the surface. This process results in smooth, continuous tones and durable output.

These printers are commonly used for photo printing, ID cards, and product customization. Their strength lies in consistency and longevity, making them suitable for applications where durability is as important as appearance.

Thermal Printers

Thermal printers produce images using heat-sensitive materials. While often associated with receipts and labels, advanced thermal models are also used in specialized graphic applications such as packaging and industrial labeling.

Thermal technology prioritizes speed and reliability over color complexity. In specific niches, it serves as a functional alternative within the graphic printer ecosystem, particularly where efficiency matters more than aesthetics.

3D Printers

Although fundamentally different from traditional printers, 3D printers are sometimes included in discussions about graphic output because they translate digital designs into physical form. Instead of ink or toner, they use materials such as plastic or resin.

3D printing is widely used in prototyping, product design, and manufacturing. While it does not produce flat graphics, it represents an extension of design-driven printing technologies beyond two-dimensional output.

Solid Ink Printers

Solid ink printers use wax-like ink blocks that are melted and applied to paper. This technology produces vibrant colors and reduces waste compared to traditional cartridges.

Although less common today, solid ink printers have been valued for their simplicity and consistent output. They remain a niche option within the graphic printer category, particularly for organizations focused on sustainability and color consistency.

Each type of printer serves a distinct role within graphic printing. From versatile inkjet and laser systems to specialized large-format and photo printers, the variety reflects the diverse needs of modern visual production. Choosing the right graphic printer depends not only on output quality, but also on workflow, media requirements, and long-term operational goals.

Benefits of Graphic Printers

The value of advanced printing equipment lies not only in its technical specifications, but also in how it supports creative, commercial, and operational goals. When visual output becomes a critical part of communication and branding, this printer offer advantages that go far beyond basic document production.

Below are the key benefits that explain why these printers are widely adopted in professional and creative environments.

Superior Print Quality

One of the most noticeable benefits is the level of visual quality that can be achieved. High resolution, refined color handling, and precise ink or toner application allow images and graphics to appear sharp, balanced, and consistent. This level of high quality graphic printing is especially important for materials such as brochures, posters, packaging, and photographic output, where visual detail directly affects perception.

Superior print quality also reduces the need for reprints. When output matches expectations from the first run, both time and resources are saved, making the entire production process more efficient.

Personalization and Customization

Modern printing increasingly favors customization. Businesses often need to personalize marketing materials, packaging, or promotional items in small batches rather than producing large, uniform runs. Advanced printers support this shift by handling variable data, design changes, and multiple versions with minimal setup.

These custom printing solutions allow companies to respond quickly to specific audiences, campaigns, or seasonal needs without compromising visual consistency. As a result, graphic printers play an important role in targeted communication strategies.

Cost-Effective for Short Runs

Traditional printing methods often become economical only at high volumes. In contrast, digital-based graphic printing systems are well suited for short runs, prototypes, and on-demand production. This flexibility reduces upfront investment and minimizes waste.

For small businesses, creative studios, and marketing teams, the ability to produce exactly what is needed—no more, no less—offers clear financial advantages. Over time, this approach can significantly lower overall production costs while maintaining professional output standards.

Fast Turnaround Times

Speed matters in competitive environments. Whether responding to a last-minute campaign or updating materials quickly, fast turnaround can be a decisive factor. Digital workflows combined with modern printing technology allow files to move from design to print with minimal delay.

Even though speed is not the primary focus, graphic printers are designed to balance performance with quality. This means complex designs can be produced quickly without sacrificing accuracy, supporting agile business operations.

Versatility Across Applications

Versatility is another major benefit. Graphic printing equipment can handle a wide range of applications, from marketing materials and signage to internal documents and creative projects. Support for different paper sizes, thicknesses, and specialty media expands what can be produced in-house.

This versatility allows organizations to consolidate multiple tasks into a single system rather than relying on external vendors or multiple devices.

Enhanced Brand Building

Consistent visual output strengthens brand identity. When colors, logos, and layouts appear uniform across all printed materials, the brand feels more cohesive and professional. Poor-quality prints, on the other hand, can weaken credibility.

By delivering reliable and repeatable output, graphic printers help businesses maintain a strong visual presence across all touchpoints, reinforcing trust and recognition over time.

Sustainability and Eco-Friendly Printing

Sustainability has become an important consideration in printing decisions. Many modern systems are designed to reduce waste, optimize ink usage, and support environmentally friendly materials. Short-run production also minimizes excess inventory and disposal.

These improvements allow organizations to balance visual quality with responsible printing practices.

Workflow Efficiency and Productivity

Finally, workflow efficiency is a key advantage. Seamless integration with design software, reliable connectivity, and predictable output reduce friction throughout the production process. Workflow efficiency printing enables teams to focus more on creative and strategic tasks rather than troubleshooting print issues.

According to Wide-Format Impressions, modern graphic printing technologies increasingly focus on delivering professional-grade output while improving efficiency and sustainability.

Drawbacks and Limitations of Graphic Printers

Despite their advantages, graphic printers are not without limitations. Understanding these drawbacks is essential for making informed decisions and setting realistic expectations.

High Initial Cost

One of the most common concerns is the initial investment. Professional-grade printing equipment typically costs more than standard office models. This includes not only the purchase price, but also accessories, software, and setup requirements.

For small organizations, this upfront cost can be a barrier, especially if printing needs are occasional rather than continuous.

Speed Limitations Compared to Offset Printing

While digital printing is flexible, it may not always match the speed or cost efficiency of offset printing for very large volumes. In high-volume production environments, offset methods can still be faster and more economical per unit.

This limitation means graphic printers are best suited for short to medium runs rather than mass production.

Print Quality and Durability Challenges

Although visual quality is generally high, durability can vary depending on ink type, media, and environmental conditions. Some outputs may be more sensitive to fading, moisture, or handling if not produced with the right materials.

Choosing appropriate consumables and finishes is essential to ensure long-lasting results.

Maintenance Requirements

Maintenance is another consideration. Advanced printing systems require regular cleaning, calibration, and part replacement to maintain optimal performance. Printer maintenance cost can add up over time, particularly in high-use environments.

Without proper upkeep, output quality and reliability may decline.

Color Consistency Issues

Color consistency across different media or print runs can be challenging. Variations in paper type, ink behavior, and environmental conditions can affect final output.

Managing these variables requires experience, proper color management, and sometimes additional tools or training.

Material and Size Limitations

Although versatile, not all printers support every material or size. Certain specialty media, extreme thicknesses, or oversized formats may require dedicated equipment.

Understanding these limits helps avoid mismatches between expectations and capabilities.

Operational Complexity

Advanced features often come with added complexity. Users may need training to fully utilize color management systems, media settings, and workflow tools.

This learning curve can slow adoption, particularly for teams without prior experience.

Setup and Calibration Time

Finally, setup and calibration can take time. Before achieving consistent results, users may need to adjust settings, test outputs, and fine-tune configurations. For organizations seeking immediate, plug-and-play solutions, this can be a drawback.

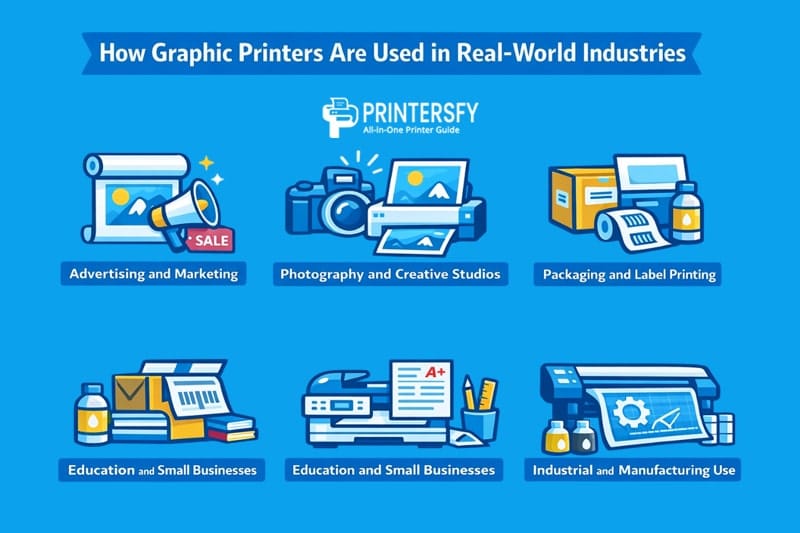

How Graphic Printers Are Used in Real-World Industries

Printing plays very different roles depending on the industry using it. In some fields, it functions as a marketing tool, while in others it supports documentation, education, or industrial processes. A graphic printer becomes especially valuable in environments where visual clarity, consistency, and flexibility are essential to daily operations.

Below are some of the most common real-world industries where advanced graphic printing technology is applied.

Advertising and Marketing

In advertising and marketing, print quality directly influences how a message is perceived. Campaign materials such as brochures, posters, banners, and point-of-sale displays rely heavily on color accuracy and sharp visuals. A graphic printer used in this context allows marketing teams to produce eye-catching materials quickly while maintaining consistent branding.

For agencies and in-house marketing departments, owning this printer for advertising purposes also provides greater control over timelines. Instead of outsourcing every revision, teams can adjust designs, test variations, and produce short runs on demand, enabling faster responses to market changes.

Photography and Creative Studios

Photography and creative studios depend on precision more than speed. Subtle differences in tone, contrast, and color temperature can dramatically affect the final output. Professional photography printing equipment is designed to reproduce images faithfully, ensuring that printed photographs match the photographer’s creative intent.

In this environment, printers are often calibrated carefully and paired with high-quality paper to achieve consistent results. Creative professionals rely on these systems not just for client work, but also for portfolios, exhibitions, and proofing. For studios that value control and consistency, a graphic printer becomes an extension of the creative workflow rather than just a production tool.

Packaging and Label Printing

Packaging and label printing place unique demands on printing equipment. Materials may include thick cardstock, adhesive labels, or specialty finishes that require precise handling. Visual consistency is critical, as packaging often represents the first physical interaction a customer has with a product.

Short production runs and frequent design updates are common in this field, especially for small brands or seasonal products. Digital graphic printing solutions allow businesses to test packaging concepts, update labels, and manage inventory without committing to large quantities upfront. In this context, the graphic printer supports both creativity and operational efficiency.

Education and Small Businesses

Educational institutions and small businesses often use printing to support communication, instruction, and branding. Schools produce teaching materials, presentations, and visual aids, while small businesses rely on printed signage, menus, and promotional materials.

Having access to reliable printing equipment reduces dependence on external vendors and allows quick adjustments. For organizations with limited budgets, the ability to produce professional-looking materials in-house can be a significant advantage. A graphic printer used in these environments balances quality and flexibility without requiring large production volumes.

Industrial and Manufacturing Use

In industrial and manufacturing settings, printing supports documentation, labeling, and product identification. Durability and consistency are often more important than aesthetics, especially for labels exposed to handling or environmental stress.

Advanced printing systems are used to produce instructional graphics, safety labels, and branded components. Although the requirements differ from creative industries, the need for reliable and repeatable output remains the same. In these scenarios, this printer contributes to operational clarity and brand consistency across physical products.

Key Factors to Consider Before Buying a Graphic Printer

Choosing the right printing equipment requires more than comparing specifications. A graphic printer represents a long-term investment, and its value depends on how well it aligns with actual usage needs, workflow demands, and budget constraints.

Below are the most important factors to consider before making a purchase.

Intended Use and Application

The first step in any graphic printer buying guide is understanding how the device will be used. Different applications place different demands on printing equipment. Designers may prioritize color accuracy and media flexibility, while businesses may focus on reliability and turnaround time.

Clarifying whether the printer will be used for photography, marketing materials, packaging, or internal documents helps narrow the options. The best graphic printer for designers, for example, may not be the most practical choice for a small office producing mixed content.

Resolution and Color Gamut

Resolution and color capability play a major role in visual output. Higher resolution supports finer detail, while a wider color gamut allows more accurate reproduction of brand colors and images.

When evaluating options, it is important to consider not just maximum DPI, but how well the printer maintains consistency across different files and media. A graphic printer with strong color management capabilities reduces the need for repeated adjustments and test prints.

Media Size and Thickness Support

Media compatibility determines what can be produced in-house. Standard office printers often struggle with thick paper, specialty finishes, or larger formats. Graphic-focused models are designed to handle a broader range of materials.

Before buying, users should consider the maximum paper size, supported thickness, and any limitations related to specialty media. These factors directly affect creative freedom and production flexibility.

Ink Technology and Cost per Print

Ink and toner systems influence both output quality and long-term expenses. Dye-based inks offer vibrant colors, while pigment-based inks provide better durability. Toner systems may be more cost-effective for higher volumes.

Understanding ink technology helps estimate the true cost per print. A graphic printer that produces excellent output but requires expensive consumables may not be the most economical choice over time.

Maintenance, Warranty, and Support

Maintenance requirements vary significantly between models. Some printers require frequent cleaning and calibration, while others are designed for minimal upkeep. Warranty coverage and manufacturer support also play a critical role in long-term reliability.

Access to service, replacement parts, and technical support should be considered, especially for business-critical environments. Reliable support can prevent downtime and protect the investment.

Software and Driver Compatibility

Finally, software compatibility should not be overlooked. Printers must integrate smoothly with design applications, operating systems, and existing workflows. Driver stability and regular updates contribute to a smoother user experience.

A graphic printer that works seamlessly with design software reduces friction between creation and production, allowing teams to focus on output rather than troubleshooting technical issues.

Maintenance and Best Practices for Graphic Printers

Proper maintenance plays a crucial role in preserving output quality and extending the lifespan of professional printing equipment. A graphic printer is designed to deliver consistent visual accuracy, but that performance depends heavily on routine care and correct handling. Without regular maintenance, even high-end devices can experience color shifts, clogged components, or reduced reliability over time.

Routine Cleaning and Printhead Care

Routine cleaning is one of the most important aspects of graphic printer maintenance. Dust, dried ink, and paper particles can accumulate inside the device and affect print quality. Regular printhead cleaning helps prevent streaks, banding, and missing details, especially in image-heavy output.

Most modern systems include automated cleaning cycles, but manual inspection is still valuable. Following manufacturer guidelines ensures cleaning processes are effective without causing unnecessary wear.

Color Calibration and Profiling

Color calibration ensures that printed output remains consistent with digital designs. Over time, variations in ink behavior, environmental conditions, or media type can affect color accuracy. Using calibration tools and profiles helps correct these shifts.

A graphic printer used in professional environments often relies on color profiling to maintain predictable results across print runs. Proper color calibration printer practices reduce wasted materials and ensure that brand colors remain consistent.

Proper Ink and Media Storage

Ink and media storage also impact long-term performance. Ink should be stored under recommended conditions to prevent drying or degradation, while paper and specialty media should be protected from humidity and dust.

By handling consumables correctly, users reduce the risk of print defects and extend the overall efficiency of a graphic printer in daily operations.

Who Should Use a Graphic Printer?

Not every user requires advanced printing capabilities. Understanding who benefits most helps clarify whether this type of equipment is a practical investment. A graphic printer is best suited for users who depend on visual accuracy and professional presentation.

Graphic Designers

Graphic designers work with detailed layouts, precise color palettes, and complex visuals. For them, consistent output is essential. A reliable printer for graphic design business use ensures that proofs, mockups, and final materials reflect the intended design without unexpected variations.

Photographers

Photographers require accurate tonal reproduction and smooth color transitions. Printing equipment that preserves fine detail and color balance allows photographers to maintain creative control from capture to final output. For professionals, a graphic printer becomes an extension of their creative process.

Print Shops and Small Businesses

Print shops and small businesses often handle diverse print jobs, from marketing materials to signage. Having in-house printing capabilities reduces turnaround time and increases flexibility. In these settings, a graphic printer supports both creative output and operational efficiency.

Enterprises and Commercial Users

Larger organizations use advanced printing systems to maintain brand consistency across departments and locations. From internal communications to external marketing, reliable printing helps ensure a cohesive visual identity at scale.

Graphics Printer vs Other Liquid Ink Printer Types

In professional and commercial printing, different liquid-ink printer technologies serve very different purposes. Although they may all use ink as the primary medium, their design goals, output quality, and use cases vary significantly. A graphic printer is built for visual accuracy and consistent color reproduction, while other ink-based printers focus on cost efficiency, volume, or specialized materials.

vs Inkjet Printer

Standard inkjet printers are widely used for home and office tasks such as documents, basic images, and occasional color printing. They rely on liquid ink sprayed onto paper, but their color management and resolution are typically optimized for general use rather than precision.

In contrast, a graphics printer emphasizes higher resolution, advanced color control, and better handling of specialty media. This makes it more suitable for design-heavy output like marketing materials, posters, and detailed visuals where accuracy matters.

vs Ink Tank Printer

Ink tank printers are a variation of inkjet technology that use refillable ink reservoirs instead of cartridges. Their main advantage is lower running cost, especially for high-volume printing. However, ink tank models usually prioritize economy over visual refinement.

While they can produce decent color output, they often lack the advanced calibration and media flexibility found in a graphics printer. As a result, ink tank printers are ideal for cost-efficient everyday printing, but less suitable for professional graphic work.

Graphics Printer vs Direct-to-Garment (DTG) Printer

DTG printers are highly specialized machines designed to print directly onto fabric using liquid textile inks. Their focus is garment decoration rather than paper-based output.

Unlike a graphics printer, which supports various paper types and visual applications, DTG printers are limited to apparel production. They excel at printing designs on clothing but are not intended for traditional graphic printing tasks.

Conclusion

Deciding whether to invest in this printer depends on how important visual quality and consistency are to your work. For users whose output directly represents a brand, product, or creative vision, the benefits often outweigh the costs.

Throughout this guide, we explored how features, printer types, real-world applications, and maintenance practices all contribute to overall value. While these devices require greater investment and care than standard office models, they also offer superior control and flexibility.

For designers, photographers, and businesses that rely on high-quality visuals, a graphic printer can streamline workflows and reduce reliance on external vendors. Advances in graphic printing technology continue to improve efficiency and sustainability, making modern systems more accessible than ever.

Ultimately, a graphic printer is worth it when visual accuracy is not optional but essential. For the right users, it becomes more than a tool—it becomes a core part of professional output and brand expression.

FAQs About Graphic Printer

What is a graphic printer used for?

A graphic printer is used for producing high-quality visual output such as marketing materials, photos, packaging, and branded graphics where color accuracy and detail matter.

Is a graphic printer different from a regular inkjet printer?

Yes. A graphic printer focuses on color precision, media flexibility, and professional output, while regular inkjet printers are designed mainly for basic documents.

Who should use a graphic printer?

Graphic designers, photographers, print shops, and businesses that rely on visual branding benefit the most from using a graphic printer.

Are graphic printers expensive to maintain?

Maintenance costs can be higher than standard printers, mainly due to ink systems, calibration, and routine cleaning, but they support better output quality.

Can a graphic printer handle short print runs?

Yes. Graphic printers are well suited for short runs and on-demand printing without sacrificing quality.