3D printing is no longer a technology reserved for industrial labs or large manufacturing companies. Over the past decade, it has quietly moved into classrooms, workshops, small studios, and even home offices. This shift did not happen because 3D printing suddenly became more powerful, but because it became more accessible. At the center of that accessibility is the FDM 3D Printer.

When people talk about 3D printing for the first time, they are almost always referring—directly or indirectly—to FDM-based 3D printing. It is the format most commonly found in consumer products, educational programs, and entry-level professional workflows. The machines are easier to understand, the materials are widely available, and the overall process feels less intimidating than other forms of additive manufacturing.

The FDM 3D Printer has earned this position by striking a balance that few technologies manage to achieve. It is simple enough for beginners to learn without frustration, yet capable enough to support serious prototyping and functional part production. Designers use it to test form and fit. Educators rely on it to explain abstract design concepts. Hobbyists adopt it as a creative tool that rewards experimentation rather than punishing mistakes.

What matters most is not just what FDM printers can produce, but how they fit into real-world learning and problem-solving. They allow ideas to move quickly from a digital sketch into a physical object that can be touched, tested, and improved. That immediacy is what makes the technology feel practical rather than theoretical.

This article is written for readers who want a clear, grounded understanding of how FDM printing works and why it has become the most widely used form of 3D printing technology today. The focus is not on selling machines or overwhelming you with specifications, but on explaining the fundamentals in a way that feels logical and connected. By starting with the basics, the role of the FDM 3D Printer within the broader world of additive manufacturing becomes easier to appreciate.

What Is an FDM 3D Printer?

An FDM 3D Printer is a machine that creates physical objects by depositing melted material in a controlled, layered manner. The term FDM stands for Fused Deposition Modeling, which describes exactly what happens during printing: material is heated, pushed through a nozzle, and fused together as it cools.

This method belongs to a broader category known as extrusion-based 3D printing. Instead of cutting material away, these printer type builds objects by adding material only where it is needed. Each layer bonds to the one below it, gradually forming a complete structure. The approach is efficient, relatively low-waste, and well suited for both simple and complex designs.

Most FDM printers use thermoplastic filament as their primary material. These filaments are supplied on spools and fed into the printer during operation. When heated, the plastic becomes soft enough to be shaped; when cooled, it hardens and retains its form. Materials such as PLA, ABS, and PETG are popular because they are predictable, affordable, and compatible with a wide range of machines. This material flexibility plays a major role in why the FDM 3D Printer is so widely adopted.

The technology’s dominance is not just anecdotal. According to Xometry, Fused Deposition Modeling is one of the most widely used 3D printing technologies due to its affordability, broad material selection, and suitability for prototyping. This assessment reflects how FDM is used across industries—not as a niche solution, but as a practical tool for iteration and early-stage development.

Another reason FDM printers remain so popular is their transparency. The printing process is visible from start to finish. Users can watch material being laid down, layer by layer, and immediately see how design choices affect the final result. For beginners, this visibility shortens the learning curve. For educators, it turns abstract design principles into tangible examples. For professionals, it offers fast feedback without complex setup.

An FDM-type 3D printer does not attempt to replace industrial manufacturing systems. Instead, it fills an important gap between concept and production. It allows users to experiment, fail, adjust, and try again with minimal cost and risk. That role—bridging digital design and physical output—is why the FDM 3D Printer continues to dominate consumer, educational, and entry-level professional markets.

How an FDM 3D Printer Works

The operation of an FDM 3D Printer follows a logical sequence that connects digital design with physical movement and controlled heat. While the process involves several technical components working together, the underlying principle remains straightforward: the printer follows instructions to place material precisely where it is needed, one layer at a time.

Industry explanations often describe this process succinctly. According to Hubs, FDM printing works by heating thermoplastic filament and depositing it layer by layer along programmed toolpaths. That description captures the core idea, but the individual stages of the process reveal why the system is both reliable and adaptable.

From Digital Model to Printed Object

Everything begins with a digital 3D model. This model defines the shape, size, and structure of the object to be printed. Before printing starts, the file is processed using slicing software, which divides the model into thin horizontal layers. Each layer represents a single pass of the printer nozzle during the build.

The slicing software converts these layers into machine instructions that guide the printer’s movements. These instructions specify where the nozzle should travel, how fast it should move, and when material should be extruded. Settings such as layer height and infill density are also defined at this stage, influencing both the appearance and strength of the final object.

Once the file is prepared, the printer begins executing the instructions. The build platform is positioned, and the FDM 3D Printer starts depositing material according to the programmed path. The same sequence repeats for each layer, creating a consistent and predictable workflow that can be paused, adjusted, or repeated as needed.

Heating, Extrusion, and Layer Bonding

At the center of the FDM printing system is the extrusion process. Thermoplastic filament is fed into a heated component where it reaches a specific extrusion temperature. At this point, the material softens enough to flow through a narrow nozzle without losing structural integrity.

As the nozzle moves, it deposits a thin strand of softened plastic onto the surface below. The material cools almost immediately, bonding to the previous layer. This bonding process is critical to the strength of the finished part. Temperatures that are too low can cause weak layer adhesion, while excessive heat can lead to deformation or loss of detail.

This cycle—extrusion, placement, cooling—repeats continuously throughout the print. Each layer depends on the stability of the one beneath it. Over time, the object takes shape, transforming from a flat outline into a fully formed three-dimensional structure. The reliability of this layer-by-layer printing approach is what allows an FDM 3D Printer to produce functional parts with relatively simple mechanics.

Seen as a whole, the FDM printing process combines motion control, thermal management, and material behavior into a system that is easy to learn yet capable of impressive results. This balance explains why FDM printing remains the most common entry point into additive manufacturing and why the FDM 3D Printer continues to serve as a foundation for learning, prototyping, and practical production.

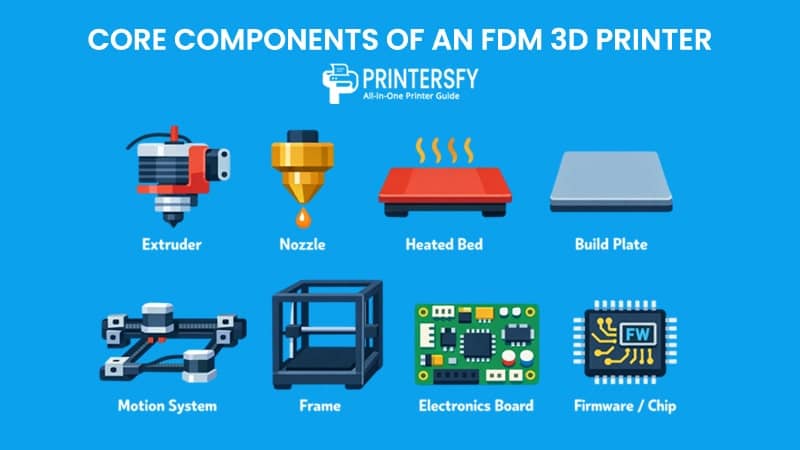

Core Components of an FDM 3D Printer

Every FDM 3D Printer is built around a small number of core components that work together in a tightly coordinated way. None of these parts are particularly mysterious on their own, but their interaction determines how reliable, accurate, and flexible the machine will be in daily use. Looking at these components individually helps explain why some printers feel stable and predictable, while others require constant adjustment.

Although designs vary between manufacturers, the basic structure of FDM hardware remains consistent. Each component serves a clear role in shaping how molten material moves, cools, and bonds into a finished object.

Extruder and Nozzle

The extruder is where the printing process truly begins. Its job is to grip the filament and push it forward at a controlled rate. This movement must be consistent. Too much pressure can cause jams or deformation, while too little leads to under-extrusion and weak layers.

Attached to the extruder is the 3D printer nozzle, a small but critical part of the system. The nozzle determines how fine the deposited material can be. Smaller nozzles allow for finer detail, while larger ones favor speed and strength. In an FDM 3D Printer, the balance between nozzle size, extrusion speed, and material flow defines the visual quality of the print.

The extruder and nozzle also handle temperature control. Filament must be heated just enough to flow smoothly without losing its structural properties. Different materials require different temperature ranges, which is why reliable thermal control is one of the most important characteristics of a capable FDM machine.

Heated Bed and Build Plate

Beneath the printing area sits the heated bed, also known as the build plate. Its purpose is not to shape the object, but to provide a stable surface for the first layers. Early layers determine whether a print will succeed or fail. If they detach or warp, everything above them becomes irrelevant.

In an FDM 3D Printer, the heated bed keeps the base of the print warm during the early stages. This reduces internal stress as the material cools, helping layers stay flat and bonded to the surface. Some materials rely heavily on bed heating, while others are more forgiving, but nearly all benefit from a controlled build surface.

Build plates come in different materials and textures, each influencing adhesion and part removal. Regardless of surface type, consistency matters more than novelty. A flat, evenly heated bed does more for print reliability than any advanced feature elsewhere in the system.

Motion System and Frame

The motion system determines how the print head and build platform move during printing. Motors, belts, rails, or lead screws guide movement along precise paths. Inaccuracies here show up immediately as misaligned layers or uneven surfaces.

A rigid frame supports this entire structure. If the frame flexes under motion, accuracy suffers. That is why even entry-level printers rely on solid construction rather than lightweight designs. The motion system and frame together define how stable the FDM 3D Printer feels during operation.

Different mechanical layouts distribute movement differently, but the goal remains the same: smooth, repeatable motion. A stable FDM machine does not draw attention to its mechanics. It simply moves as expected, layer after layer.

Electronics and Firmware

Behind the physical movement lies the controller board and firmware. This is the system’s nervous center. It interprets instructions, regulates temperatures, and coordinates motion across all axes.

The controller board manages communication between software and hardware. It ensures motors move in sync, heaters maintain stable temperatures, and safety limits are respected. Firmware defines how responsive the system feels and how it reacts to changes during printing.

In practice, users rarely interact directly with these components, but their quality influences every print. Reliable electronics make an FDM 3D Printer feel predictable rather than temperamental. When problems arise, they are easier to diagnose and resolve because the system behaves consistently.

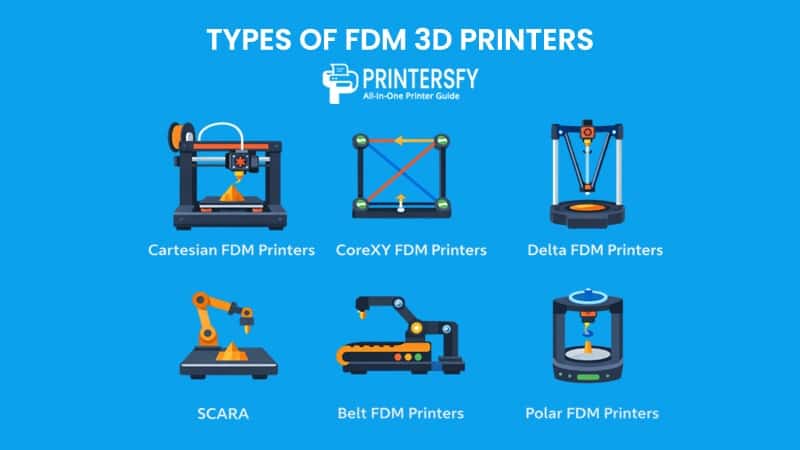

Types of FDM 3D Printers Based on Motion Systems

While the core components of an FDM 3D Printer remain similar, the way those components move can differ significantly. These differences define the printer’s motion system, also known as its mechanical architecture. Motion systems determine how speed, accuracy, and build volume are balanced.

Understanding FDM printer types helps explain why some machines prioritize simplicity while others aim for higher performance or unconventional form factors.

Cartesian FDM Printers

Cartesian systems are the most common and easiest to visualize. Movement occurs along three perpendicular axes, typically labeled X, Y, and Z. Each axis moves independently, making the system intuitive and straightforward.

In a Cartesian 3D printer, either the print head or the build plate moves along each axis. This simplicity makes the design easy to manufacture and maintain. For many users, Cartesian printers feel predictable and forgiving, which is why they dominate beginner and educational markets.

This design favors reliability over speed. While not the fastest option, Cartesian motion systems provide consistent results and are widely supported by software and accessories. As a result, they remain a foundational design for many FDM 3D Printer models.

CoreXY FDM Printers

CoreXY systems approach movement differently. Instead of moving axes independently, they use a paired belt system that allows the print head to move along two axes simultaneously. This reduces moving mass and allows for faster, more precise motion.

The CoreXY mechanism is often found in more advanced FDM machines. It offers improved speed without sacrificing accuracy, but it requires more careful assembly and tuning. Belt tension and alignment play a larger role, which means setup quality matters.

For users willing to invest time in calibration, CoreXY printers deliver smooth motion and efficient printing. They represent a step toward higher-performance FDM motion systems while remaining accessible to non-industrial users.

Delta FDM Printers

Delta systems are visually distinctive. Instead of moving along linear rails, a Delta 3D printer uses three vertical arms connected to a central print head. Coordinated movement of these arms positions the nozzle within the build area.

This design allows for fast, fluid motion, particularly on tall prints. Delta printers often excel at speed and continuous movement. However, their kinematics are more complex, making calibration less intuitive.

Delta systems reward precision in setup. When tuned correctly, they produce smooth prints, but they demand more attention than Cartesian designs. In the context of an FDM 3D Printer, Delta systems trade simplicity for elegance and speed.

SCARA (Selective Compliance Articulated Robot Arm)

SCARA-based printers use a robotic arm rather than linear rails. Movement occurs through rotational joints, similar to industrial robotic systems. This design is less common but offers unique advantages.

The SCARA robot arm allows for fast, sweeping motion with fewer moving parts. However, maintaining accuracy across the entire build area is challenging. These systems require advanced calibration and control algorithms.

In most consumer contexts, SCARA designs remain experimental. They demonstrate what is possible within FDM motion systems but are not yet mainstream.

Belt FDM Printers

Belt printers take a different approach by using a moving conveyor belt as the build surface. This allows prints to extend indefinitely in one direction and enables continuous printing.

The belt 3D printer changes how parts are oriented and removed. Prints slide off the belt as they complete, making automation possible. However, this system introduces complexity in print orientation and layer bonding.

Belt printers appeal to niche use cases rather than general users. They expand what an FDM 3D Printer can do but require careful design considerations.

Polar FDM Printers

Polar systems use polar coordinates instead of linear axes. The build plate rotates while the print head moves radially. This reduces mechanical complexity but complicates software control.

Polar printers are rare and often experimental. While they demonstrate alternative approaches to motion systems, they remain outside mainstream adoption due to limited support and complexity.

Filament Materials Used in FDM 3D Printing

The capabilities of an FDM 3D Printer are closely tied to the materials it uses. While the machine controls motion and temperature, filament determines how a printed object behaves in the real world—how strong it feels, how flexible it is, and how well it holds its shape over time. This is why filament selection is not a secondary concern, but a central part of working with any FDM filament system.

All filaments used in FDM printing belong to a broader category of thermoplastic materials. These plastics soften when heated and solidify as they cool, allowing them to be shaped repeatedly without permanent chemical change. Within that category, however, each filament behaves differently, and those differences matter in practice.

PLA — The Beginner-Friendly Filament

PLA filament is often the first material people encounter when using an FDM 3D Printer, and for good reason. It prints at relatively low temperatures, adheres easily to most build surfaces, and produces consistent results with minimal adjustment. For beginners, this reliability removes much of the frustration associated with early printing attempts.

PLA also tends to produce clean edges and smooth surfaces compared to many other materials. This makes it popular for visual models, educational projects, and household items that are not exposed to heat or heavy mechanical stress. Its rigidity helps maintain dimensional accuracy, especially on simpler designs.

However, PLA’s ease of use comes with trade-offs. It softens at relatively low temperatures and can become brittle over time. These limitations make it less suitable for functional parts that must endure heat, load, or outdoor conditions. Even so, as an entry point into FDM printing, PLA remains unmatched in accessibility.

ABS — Strength and Heat Resistance

ABS filament represents a step toward more demanding applications. It offers higher strength and better heat resistance than PLA, which makes it suitable for printers parts exposed to mechanical stress or elevated temperatures. Many functional prototypes and enclosures rely on ABS for this reason.

Printing ABS on an FDM 3D Printer requires more control. Higher extrusion temperatures and a heated bed are typically necessary to prevent warping and layer separation. Without proper temperature management, prints may curl or crack during cooling.

Because of these requirements, ABS is often introduced after users gain confidence with simpler materials. When handled correctly, it produces durable parts with long-term stability, but it rewards careful setup rather than casual experimentation.

PETG and TPU — Flexibility and Durability

PETG filament occupies a middle ground between PLA and ABS. It combines ease of printing with improved toughness and moisture resistance. PETG is less brittle than PLA and easier to manage than ABS, making it a common choice for functional prints that still need reliable output.

TPU filament, by contrast, introduces flexibility. It allows an FDM 3D Printer to produce parts that bend, compress, or absorb impact. This opens the door to applications such as gaskets, protective covers, and wearable components.

Flexible materials require slower print speeds and careful extrusion control. When tuned properly, they expand what FDM printing can achieve beyond rigid objects, reinforcing the importance of material choice within the FDM filament system.

FDM Filament Comparison

| Material | Strength | Print Difficulty | Temperature Range | Typical Use |

|---|---|---|---|---|

| PLA | Moderate | Easy | Low | Visual models, education |

| ABS | High | Moderate–Hard | High | Functional parts, enclosures |

| PETG | High | Moderate | Medium | Durable components, containers |

| TPU | Variable | Moderate–Hard | Medium | Flexible parts, protective items |

Advantages of FDM 3D Printers

The widespread adoption of the FDM 3D Printer is not accidental. It reflects a set of advantages that align well with how most people learn, prototype, and create. These strengths explain why FDM technology remains dominant even as alternative printing methods evolve.

Cost and Accessibility

One of the most significant advantages of FDM printing is affordability. Compared to other additive manufacturing methods, low-cost 3D printing is where FDM excels. Machines, replacement parts, and materials are widely available, reducing barriers to entry.

This accessibility allows users to experiment freely. Mistakes are not expensive, and iteration feels natural rather than risky. For many, this is the difference between observing 3D printing from a distance and actively engaging with it.

Material Variety

Material versatility is another defining strength. An FDM 3D Printer can work with a wide range of thermoplastics, each suited to different applications. From rigid display models to flexible functional components, the same machine can adapt through material choice alone.

This versatility supports experimentation and learning. Users can adjust properties such as strength, flexibility, and durability without changing hardware, making FDM a flexible platform rather than a single-purpose tool.

Ideal for Learning and Prototyping

FDM printers are widely recognized as beginner-friendly 3D printers. Their visible process and forgiving materials make them well suited for education and early-stage design work. Students can observe how changes in settings affect results, reinforcing practical understanding.

For prototyping, speed matters more than perfection. FDM printing allows rapid iteration, enabling designers to test ideas, refine dimensions, and validate concepts before moving to more specialized manufacturing methods.

Limitations of FDM 3D Printers

Despite its strengths, the FDM 3D Printer has clear limitations. These constraints do not invalidate the technology, but they shape how and when it should be used.

Surface Quality

One of the most visible limitations of FDM printing is surface finish. Because objects are built layer by layer, layer lines are often visible on the finished part. While post-processing can reduce their appearance, the process rarely matches the smooth surfaces produced by resin-based systems.

For applications where aesthetics or fine detail matter, this limitation becomes significant. FDM printing prioritizes function and accessibility over visual perfection.

Precision Compared to Other Technologies

Dimensional accuracy is another area where FDM printing shows constraints. While modern machines are capable of impressive precision, factors such as material shrinkage, cooling behavior, and mechanical tolerances influence results.

Compared to other additive manufacturing methods, FDM printing limitations become apparent in applications requiring tight tolerances or micro-scale detail. In these cases, FDM often serves as a stepping stone rather than a final solution.

FDM vs SLA vs SLS: Comparing 3D Printing Technologies

Within the broader landscape of additive manufacturing, different 3D printer technologies are designed to solve different problems. While the FDM 3D Printer is often the first system most people encounter, it operates alongside other methods such as SLA and SLS, each with distinct strengths and trade-offs. Looking at these technologies side by side helps clarify when FDM is the right choice—and when it is not.

FDM 3D Printing: Accessibility and Practicality

The FDM printing method is built around simplicity. It works by melting thermoplastic filament and depositing it layer by layer to form an object. This approach emphasizes affordability, material availability, and mechanical reliability.

Because FDM systems are relatively easy to operate and maintain, they are widely used in education, home workshops, and early-stage product development. The trade-off lies in surface quality. Layer lines are often visible, and fine details may require post-processing. Even so, for many real-world applications, this balance between usability and output quality is precisely what makes the FDM 3D Printer so practical.

SLA 3D Printing: Precision and Surface Detail

SLA 3D printing takes a fundamentally different approach. Instead of filament, it relies on liquid resin that is cured using controlled light exposure. This allows SLA systems to achieve much higher resolution and smoother surfaces compared to FDM.

As a result, resin 3D printer setups are commonly used for dental models, jewelry prototypes, and detailed visual parts. However, the workflow is more demanding. Resin handling, cleaning, and post-curing add complexity, and material costs are generally higher. SLA excels in precision, but it sacrifices the simplicity and flexibility associated with FDM technology.

SLS 3D Printing: Strength and Industrial Applications

SLS 3D printing belongs to the category of powder-based printing. In this process, a laser selectively fuses powdered material into solid structures. Because the surrounding powder acts as natural support, SLS can produce complex geometries without additional support structures.

This strength and design freedom make SLS attractive for industrial manufacturing and functional end-use parts. The downside is accessibility. SLS equipment is expensive, space-intensive, and typically unsuitable for small workshops or educational environments. Compared to the FDM 3D Printer, SLS prioritizes performance over approachability.

Choosing Between FDM, SLA, and SLS

When compared directly, these technologies do not compete as much as they complement one another. FDM offers balance and accessibility, SLA delivers visual precision, and SLS provides industrial-grade strength. The right choice depends less on technical superiority and more on context—budget, skill level, and intended use.

FDM vs SLA vs SLS Comparison

| Technology | Materials | Cost | Accuracy | Typical Users |

|---|---|---|---|---|

| FDM 3D Printer | Thermoplastic filament | Low | Moderate | Beginners, education, prototyping |

| SLA 3D Printer | Liquid resin | Medium | High | Designers, dental, jewelry |

| SLS 3D Printer | Powdered polymers | High | High | Industrial manufacturing |

Rather than asking which technology is best overall, it is more useful to ask which one fits the task at hand. In that comparison, the FDM 3D Printer continues to stand out as the most accessible and adaptable option for learning, experimentation, and everyday fabrication.

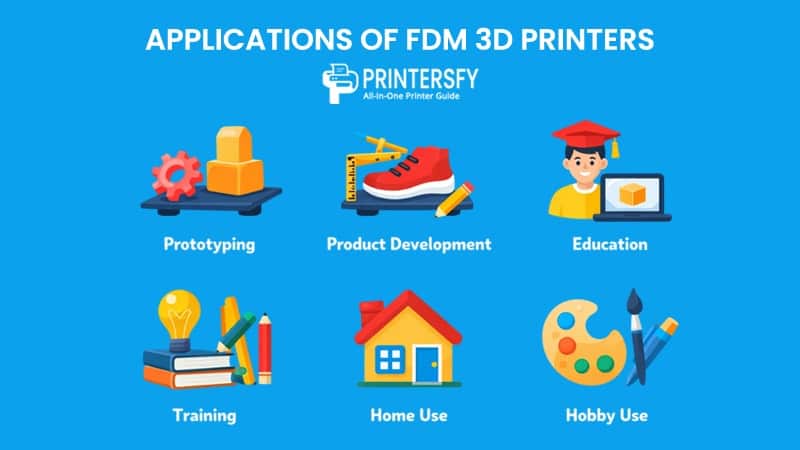

Applications of FDM 3D Printers

The value of an FDM 3D Printer becomes most apparent when looking at how it is used in everyday contexts. Its design favors adaptability, allowing the same machine to support learning, experimentation, and functional output without specialized infrastructure.

Prototyping and Product Development

In product development, speed matters. Designers and engineers rely on rapid prototyping to test ideas before committing to costly manufacturing processes. An FDM 3D Printer allows concepts to be printed, evaluated, adjusted, and reprinted within hours rather than weeks.

This quick turnaround supports creative exploration. Early prototypes do not need to be perfect; they need to exist. FDM printing enables that step, helping teams identify design flaws and improve functionality long before final production.

Education and Training

Educational 3D printing is one of the strongest use cases for FDM technology. Its visible process and approachable materials make it ideal for teaching design principles, engineering basics, and problem-solving skills.

Students can connect digital models to physical outcomes in a tangible way. Mistakes become learning opportunities rather than setbacks, reinforcing experimentation and iteration. For institutions, the reliability and affordability of FDM systems make them practical teaching tools rather than fragile demonstrations.

Home and Hobby Use

Home 3D printing thrives on flexibility, and FDM systems deliver exactly that. Hobbyists use them to create tools, organizers, replacement parts, and creative projects tailored to personal needs.

Because materials are widely available and relatively inexpensive, experimentation feels approachable. Users are free to try new designs, adjust settings, and learn through hands-on experience. In this environment, the FDM 3D Printer functions less as a machine and more as a creative extension of the user’s ideas.

What to Consider Before Using or Buying an FDM 3D Printer

Choosing an FDM 3D Printer is less about finding the most advanced machine and more about understanding how the printer fits into your workflow. The best FDM 3D printer for one user may not be the right choice for another, especially when daily use, materials, and learning curve are taken into account.

While many models share similar core features, small differences in specifications and software support can have a significant impact on long-term usability. Looking at a few key factors early helps avoid frustration and sets clearer expectations from the start.

Print Size and Specifications

One of the first things to consider is build volume. This defines the maximum size of objects the printer can produce in a single print. A larger build volume offers flexibility, but it also increases the machine’s footprint and, in some cases, its complexity.

Printer specifications go beyond size alone. Factors such as maximum nozzle temperature, heated bed capability, and motion system design influence what materials the printer can handle and how consistently it performs. An FDM 3D Printer intended for learning or light prototyping does not need extreme specifications, but it should offer stable operation within its intended range.

It is often more practical to choose a printer that comfortably meets your current needs rather than one that promises future capabilities you may never use. Reliability and ease of adjustment tend to matter more than raw numbers on a specification sheet.

Material Compatibility

Material compatibility shapes what you can realistically print. While most FDM machines handle common thermoplastics such as PLA without issue, more demanding materials place higher demands on hardware and temperature control.

An FDM 3D Printer with a heated bed and enclosed build area offers more flexibility when working with materials like ABS or PETG. Without these features, prints may still be possible, but consistency becomes harder to achieve. Understanding which materials you plan to use helps narrow down suitable options quickly.

Material choice also affects maintenance and learning curve. Some filaments are forgiving and stable, while others require careful tuning. Matching printer capabilities to material expectations keeps the experience productive rather than discouraging.

The Role of Drivers and Software

Beyond hardware, software plays a quiet but critical role in daily operation. Every FDM 3D Printer relies on slicer software to translate digital models into machine instructions. These tools control layer height, print speed, and material flow, shaping both quality and reliability.

The FDM printer driver acts as a bridge between software and hardware, ensuring that instructions are interpreted correctly by the machine. Driver stability influences how smoothly the printer communicates with the computer and how reliably prints start and finish.

At a high level, drivers and slicer software determine whether a printer feels intuitive or unpredictable. While this article does not dive into installation or troubleshooting, these components deserve attention during setup. A dedicated guide on FDM printer drivers explores this topic in greater depth and helps users build a stable printing environment.

Conclusion

The FDM 3D Printer has earned its position as the most widely used form of 3D printing by focusing on practicality rather than extremes. It does not aim to deliver the finest surface finish or industrial-grade strength by default. Instead, it offers a balance that makes additive manufacturing accessible to a broad audience.

Within the wider 3D printing ecosystem, FDM stands out as an entry point that encourages experimentation and learning. Its combination of affordable hardware, versatile materials, and visible printing processes allows users to move from idea to object without unnecessary barriers.

For education, prototyping, and everyday problem-solving, the FDM 3D Printer continues to serve as a foundation technology. It supports entry-level manufacturing while remaining relevant to professionals who value speed and flexibility. That balance explains why, despite constant innovation in other areas, FDM printing remains a central pillar of modern 3D printing.

FAQs About FDM 3D Printer

What is FDM in 3D printing?

FDM stands for Fused Deposition Modeling. It is a 3D printing method where thermoplastic filament is melted and deposited layer by layer to create an object.

Are FDM and PLA the same?

No. FDM refers to the printing technology, while PLA is a type of material used in that technology. PLA is one of several filaments compatible with FDM printing.

Is FDM stronger than SLA?

Strength depends on design and material choice. FDM prints are often mechanically stronger for functional parts, while SLA excels in surface detail rather than durability.

Is FDM normal 3D printing?

In many contexts, yes. When people refer to “normal” or standard 3D printing, they are usually describing FDM because it is the most common and accessible method.

Is FDM better than resin?

Neither is universally better. FDM offers simplicity and material versatility, while resin printing delivers higher detail and smoother surfaces. The better choice depends on the intended application.