Long before modern inkjet printers and laser printers took over offices around the world, the Daisy Wheel Printer set the standard for what “professional” printed text should look like. If you’ve ever held an old legal document or a perfectly typed letter from the 1980s, chances are it came from this machine. Clean strokes, sharp edges, no pixelation—just pure, typewriter-level precision. And that’s exactly what made people trust it.

The charm of the daisy wheel isn’t just nostalgia; it’s the way the machine works. Instead of spraying ink or fusing toner, every character is physically struck onto the page. A small “wheel” filled with raised letters spins rapidly, positioning the right character in front of a hammer that snaps forward to hit the ribbon and transfer the imprint onto paper. It’s mechanical, deliberate, and incredibly consistent. There’s something fascinating about how such a simple mechanism delivered such reliable, high-quality text at a time when computing technology was still in its infancy.

What makes it even more interesting is how it sits at the intersection of typewriter heritage and digital printing. It relied on the durability of impact printing but was driven by early computer commands. That combination made it a favorite for law offices, government institutions, banks, and any environment that demanded sharp, formal text without room for errors.

In this article, we’re going to break down exactly how this printer type works, what components make it so precise, why some industries continued using it long after newer technologies arrived, and where it still finds niche use today. You’ll see its strengths, its limitations, and how it compares to other impact printers of the same era. By the end, you’ll understand why this classic machine remains a benchmark for text clarity—and why its legacy still matters.

What Is a Daisy Wheel Printer?

A Daisy Wheel Printer is one of the earliest machines to deliver true letter-quality printing in the era before inkjet and laser technologies. Unlike graphic-capable printers, this device specializes in producing clean, sharp text by physically striking raised characters onto paper.

Despite its vintage status, it played a crucial role in shaping the expectations for professional document output and became a bridge between traditional typewriters and early digital printers.

Definition & Concept

At its core, a Daisy Wheel Printer is a type of impact printer designed to produce highly consistent, typewriter-style text. The name comes from the shape of its print wheel: a circular disk with “petals,” each containing a raised character such as letters, numbers, or punctuation.

When printing, the wheel spins rapidly to position the correct character in front of a hammer, which then strikes it through an inked ribbon and onto the page. This mechanical impact is what gives the printer its distinctive crisp look—something early computer users valued for contracts, official letters, and business communication.

What sets the Daisy Wheel Printer apart from other impact printers is its superior text clarity. Dot matrix printers, for example, use a grid of tiny pins to form characters, which results in a visibly lower resolution.

In contrast, the daisy wheel produces fully formed characters, making it one of the earliest machines capable of achieving true letter-quality output. This made it a trusted device in offices that required precision and formality long before high-resolution digital printers existed.

Another defining trait is its limitation: it can only print text, not graphics. While this might sound restrictive today, it was a deliberate choice during its time. The goal was accuracy, reliability, and clean typography—qualities that daisy wheel technology delivered exceptionally well.

Historical Background

The origins of the Daisy Wheel Printer trace back to the early 1970s, when manufacturers sought a way to bring typewriter-level quality into the rapidly expanding world of personal and business computing.

At that time, most early computer printers were noisy, crude, and unable to deliver high-quality text. The introduction of the daisy wheel changed the game by offering documents that looked professional enough for legal, financial, and corporate use.

By the late 1970s and throughout the 1980s, daisy wheel technology reached its peak adoption. Brands like Diablo, Smith Corona, and Epson released models that became staples in offices, word processing centers, and government institutions. It represented a major step forward in printing technology history, giving businesses a dependable tool for producing consistent, error-free text.

Its popularity eventually declined as inkjet and laser printers emerged, offering faster speeds and the ability to print graphics. Still, the daisy wheel holds a special place in printing evolution—an influential bridge between mechanical typewriters and modern digital output.

How a Daisy Wheel Printer Works

At a glance, a Daisy Wheel Printer doesn’t look like anything special—just a wheel, a motor, and a few metal printers parts. But once it starts printing, you can see how each piece plays its part. The wheel spins, the hammer snaps forward, and the ribbon transfers ink to the page. Nothing fancy, just a clean mechanical process that does exactly what it needs to do.

What makes it interesting is how early computers controlled all this movement. The machine wasn’t smart by today’s standards, but it responded quickly to character commands: pick the right letter, move it into place, hit the page, then move on. When everything is aligned correctly, the result is that familiar, sharp text people trusted for official documents. There’s no mystery to it—just straightforward engineering that worked surprisingly well for its time.

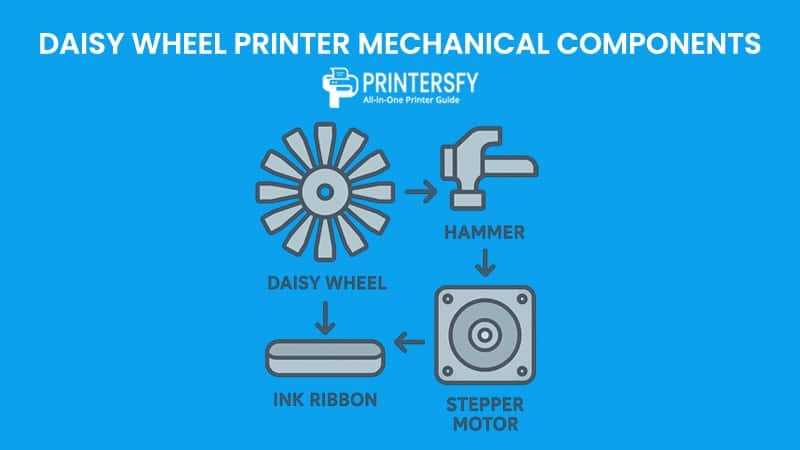

Mechanical Components

At the heart of the Daisy Wheel Printer lies a set of mechanical components that work together with remarkable coordination. The first and most defining component is the wheel—a circular disk resembling a daisy flower, with each “petal” carrying a raised character.

These petals represent letters, numbers, punctuation marks, and sometimes special symbols. The wheel spins at high speed, allowing characters to be positioned quickly and accurately.

Next is the hammer mechanism, responsible for striking each character onto the paper. When the wheel aligns the correct petal in front of the print position, a small solenoid-driven hammer snaps forward. This impact forces the raised character through an inked ribbon and onto the paper surface.

The hammer must be both strong and precise; too light, and the print becomes faint; too strong, and the paper may tear. This balance is part of what contributed to the consistent output the printer was known for.

The ribbon is another important element—an inked strip placed between the hammer and the paper. Unlike modern cartridges, this ribbon does not spray or diffuse ink. Instead, it transfers ink through direct impact, creating sharp, fully formed letters. Combined with the rigid metal characters on the wheel, it enables crisp text that other early impact printers couldn’t match.

Finally, the stepper motor controls the rotation of the wheel and the movement of the carriage. This motor must align characters with incredible accuracy, ensuring that every strike occurs at the right moment.

Together, these components create a system that embodies the essentials of daisy wheel components and delivers the signature clarity associated with the technology. It’s a beautiful example of simple mechanics achieving professional-quality results through precision engineering—something many printing enthusiasts still admire today.

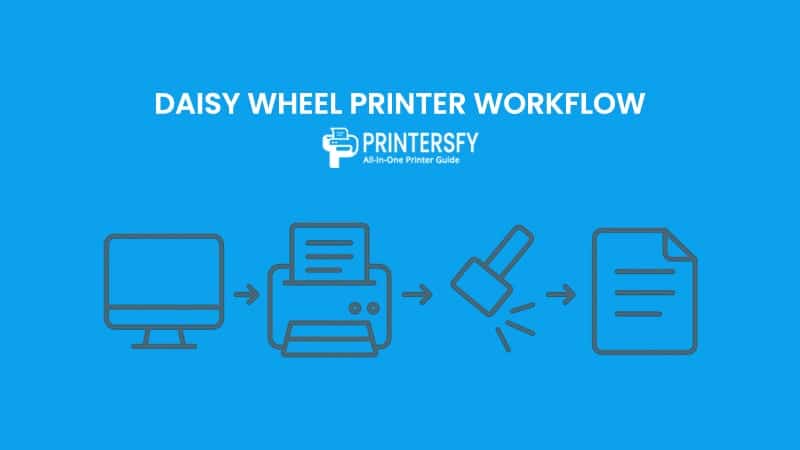

Printing Process Step-by-Step

To understand the workflow of a Daisy Wheel Printer, imagine the printing process as a sequence of controlled mechanical actions triggered by digital commands. Everything begins when the computer sends character data to the printer’s controller. This internal controller interprets the data, determining which character needs to be placed on the paper next.

Once the controller identifies the character, the stepper motor rotates the wheel until the correct petal is positioned in front of the print point. This alignment must be incredibly fast and accurate because the printer repeats this process for every single character in a line.

After alignment, the hammer mechanism activates. The hammer strikes the back of the selected character, pushing it through the inked ribbon. This impact transfers the ink onto the paper, forming a perfectly shaped letter. The process is repeated—alignment, strike, alignment, strike—for every character in the document.

As printing continues, the carriage or the paper feed moves horizontally or vertically, depending on the printer model. This ensures proper positioning for the next character or line. Although the entire process may sound slow compared to modern standards, it was highly efficient for its time.

This workflow exemplifies the principles of the impact printing process, where precision timing and mechanical force work together to produce text. And because each character is a fully formed metal imprint rather than a matrix of dots, the result is consistent, sharp, and professional—exactly what offices, government agencies, and legal departments needed.

Workflow Diagram

To make the process easier to visualize, here’s a simplified text-based workflow diagram showing how a Daisy Wheel Printer executes each print command:

[Computer Input]

│

▼

[Printer Controller Receives Character Data]

│

▼

[Stepper Motor Rotates Wheel]

│

▼

[Correct Petal Positioned in Print Area]

│

▼

[Hammer Strikes Character]

│

▼

[Ink Ribbon Transfers Imprint to Paper]

│

▼

[Carriage/Paper Advances to Next Position]

│

▼

[Cycle Repeats for Each Character]

This diagram represents the core mechanics behind the system—digital commands converted into physical action. It’s a perfect example of typewriter-style printing enhanced with the logic of early computing, blending mechanical precision with programmed control.

Even today, it’s impressive how tightly coordinated each step must be to maintain the text quality that made the daisy wheel famous.

Characteristics of Daisy Wheel Printers

The characteristics of a Daisy Wheel Printer reveal exactly why this device became a benchmark for professional text output in the early days of personal computing. Its mechanical foundation, rigid components, and consistent strike-based printing made it stand out long before digital printing matured.

This section breaks down its physical attributes, printing behavior, and the built-in limitations that shaped its role in offices and institutions.

Physical Characteristics

The Daisy Wheel Printer is known for its solid construction and unmistakable mechanical design. Built to endure repeated impact cycles, these machines were heavier and more robust than the lightweight inkjet printers that came decades later. Their engineering focused on precision and longevity, making them ideal for environments that needed dependable, error-free text output day after day.

Cartridge wheel

The heart of the system is the interchangeable cartridge wheel. Each wheel holds a complete set of raised characters mounted on thin, petal-like arms radiating from a central hub. Swapping wheels allowed users to change typefaces, symbol sets, or language options. Although this process required manual replacement, it guaranteed perfectly formed characters with consistent depth and clarity.

Mechanical sound

A defining characteristic of the printer is its distinctive mechanical sound. Because every character is produced through a hammer impact, printing generates a rhythmic tapping—almost like a typewriter driven by a computer. While loud by today’s standards, this sound was widely accepted in offices of the time and often associated with reliability and precision.

Build quality

Durability was a major strength. Internal components such as hammer solenoids, metal shafts, and stepper motors were engineered to withstand years of heavy use. Precision mechanics were essential since any misalignment could affect print quality. As a result, many daisy wheel units continued functioning long after newer technologies appeared, earning a reputation for longevity.

Printing Characteristics

In terms of output, the Daisy Wheel Printer excelled in producing crisp, highly readable text. It wasn’t designed for versatility, but within the domain of text-only printing, few early printers could match its results.

Letter-quality output (LQ)

The standout feature is its true letter-quality output. Unlike dot matrix printers that build characters from small pin patterns, the daisy wheel prints fully formed, solid characters. This produced clean, sharp text suitable for legal documents, business correspondence, and any situation demanding a professional appearance.

Slow printing speed (10–75 cps)

However, this precision came at the expense of speed. Most models operated at 10 to 75 characters per second, which is extremely slow by modern standards. The printer had to rotate the wheel, align the correct petal, and complete a hammer strike for every single character. While slow, the trade-off was acceptable to users who prioritized quality over throughput.

Character consistency

Consistency was one of its biggest strengths. Because each letter came from a fixed metal shape, every character printed looked identical—same width, same thickness, same form. This uniformity gave documents a polished look that early impact printers struggled to achieve.

Limitations in Character Variety

Despite its strengths, the Daisy Wheel Printer had inherent mechanical limitations that eventually constrained its relevance as printing needs evolved.

Requires wheel changes for different fonts

Font changes were not digital. To use a different typeface or symbol set, users had to swap the entire wheel manually. Although functional, this process slowed workflow and made font flexibility impractical compared to modern printers.

Text-only printing (no graphics)

The most significant limitation is that the printer can only produce text. Since each character is a fixed metal shape, the machine cannot render images, logos, charts, or any kind of graphic output. This text-only printing capability limited its usefulness as businesses demanded more visual and graphical elements in documents. Ultimately, this restriction played a major role in the shift toward inkjet and laser technologies.

Examples of Daisy Wheel Printers

The evolution of the Daisy Wheel Printer can be seen clearly through the machines that defined each era of its development. Certain models became office staples because of their reliability and crisp text, while others carved out a reputation in more specialized roles.

Looking at these printers gives us a practical sense of how the technology was used, what made certain units stand out, and why a handful of them continued operating long after the mainstream market moved on.

Popular Models in History

Some of the most well-known examples of the Daisy Wheel Printer came from brands that were pioneers in early computer peripherals. These models shaped the expectations for letter-quality printing and set performance standards during the technology’s peak years.

Diablo 630

The Diablo 630 is widely considered the gold standard of daisy wheel technology. Released in the late 1970s, it quickly became popular thanks to its durability, crisp output, and relatively fast print speed for its era. Many other manufacturers later copied its design, which speaks to its influence and engineering quality.

Smith Corona XD series

Smith Corona, a company synonymous with typewriters, transitioned smoothly into digital printing with the XD series. These models offered excellent character clarity and were known for their quiet operation compared to competing devices. Their hybrid typewriter-printer design appealed to offices transitioning from manual to digital workflows.

Epson RX series

Epson’s RX line brought improved reliability and broader compatibility with early home and business computers. The models were praised for their ease of maintenance and consistent output, making them a practical choice for institutions that needed dependable letter-quality printing on a daily basis.

Modern Niche Usage

Although the Daisy Wheel Printer is no longer mainstream, it still finds use in narrow but important niches. Some industries continue to value the machine’s text precision, impact-based output, and long-term durability—qualities modern printers can’t always replicate.

Industries that still use them

A handful of industries still rely on daisy wheel units due to strict requirements for impact-based, non-erasable text. Certain banking environments, archival offices, and authentication departments use them because the printed text cannot be easily altered. For these specialized tasks, the mechanical imprint offers a level of security that digital printing methods do not match.

Legal and document verification

In legal environments, some agencies continue using daisy wheel machines for document verification, form imprinting, and official records. The physical impression left on the paper makes tampering more difficult, which adds an extra layer of authenticity. While considered vintage printer technology, it remains surprisingly practical for forms that require clear, permanent text impressions.

Even today, the Daisy Wheel Printer retains value in roles where reliability, permanence, and text clarity are more important than speed or graphical capability. That longevity says a lot about how well the technology was engineered—and why certain users never fully moved away from it.

Advantages of Daisy Wheel Printers

The strengths of the Daisy Wheel Printer come from its simple mechanical design and the way it produces text. Even with all the newer printing technologies available today, there are a few advantages that still make this machine stand out in specific situations.

High Letter Quality Output

One of the biggest reasons people used Daisy Wheel printers in the past was the text quality. The printer creates letters using solid metal characters, so every stroke is crisp and fully formed—very similar to a professional typewriter.

This made the Daisy Wheel Printer a dependable choice for legal documents, contracts, and other paperwork where clarity really mattered. Because each character is stamped, not constructed from tiny dots, the output often looked cleaner than early dot matrix printers, especially when viewed up close.

Permanent & Durable Print

Another advantage is the durability of the printed text. Since the machine uses an impact method, the ribbon presses ink deeply into the paper fibers. The result is text that’s hard to smudge and tends to hold up well over time. Many documents printed decades ago using this method are still readable today. In environments that needed a form of print permanence—such as financial institutions or archive departments—this was a huge plus.

This durability ties closely to the nature of impact printing durability, where the physical strike gives the ink a more permanent bond compared to the lighter touch of early inkjet systems. In practical terms, this meant the Daisy Wheel Printer was often used for records that had to be stored for long periods.

Consistency & Professional Appearance

Consistency was another area where the printer performed extremely well. Since all characters come from fixed metal shapes, there’s no variation in thickness or style from one letter to the next. That uniformity gave documents a polished, professional look that businesses appreciated.

Even in long print jobs, the machine maintained steady character placement and density. For offices that valued clean presentation over speed, the Daisy Wheel Printer offered exactly what they needed, and it did so in a very reliable way.

Disadvantages of Daisy Wheel Printers

While the technology had its strengths, it also came with several drawbacks that eventually limited its long-term appeal. As printing needs grew more complex, these limitations became more noticeable, especially when faster and more flexible printers entered the market.

Slow Printing Speed

Speed is easily the biggest weakness. Most daisy wheel models print character by character, which takes time—typically anywhere from 10 to 75 characters per second. For large documents, this feels slow, especially compared to laser or inkjet printers that can cover whole pages in seconds.

Even during its peak, many offices used the Daisy Wheel Printer mainly for final copies, using faster printers or word processors for drafts. The slow pace was simply part of the trade-off for high-quality text.

No Graphics Support

Another major limitation is the lack of graphics. The machine can only print characters that physically exist on its wheel, which makes images, charts, logos, and diagrams impossible to produce. For a while, this wasn’t a big problem—most documents in the early days of computing were text-based.

But as businesses began using more visuals, the Daisy Wheel Printer struggled to keep up. This limitation became one of the clearest signs that the technology wasn’t built for the long run, especially as digital publishing and desktop graphics started to grow.

High Noise Level

Noise is another disadvantage that users had to accept. The hammer strikes inside the printer are loud and repetitive, and the overall operation produces a constant mechanical clatter. In a quiet office, this can be distracting, especially during long print jobs. The sound is a direct result of the impact mechanism and can’t be reduced much without affecting print quality.

Because of this, many offices placed these printers in separate areas to keep the noise level down. The loud operation became a defining trait of the machine, often associated with mechanical noise printer characteristics—but not always in a positive way.

Despite these weaknesses, the Daisy Wheel Printer left a strong legacy. Its disadvantages didn’t erase its strengths, but they did highlight why the world eventually moved on to faster, quieter, and more versatile options.

Uses of Daisy Wheel Printers

Even though the Daisy Wheel Printer is no longer a mainstream office tool, there was a time when it played a central role in business operations, government workflows, and long-term record keeping. Its mechanical precision, impact-based printing, and reliable text output made it suitable for work that required clarity and permanence.

Business & Office Environments

In the early years of computer adoption, the Daisy Wheel Printer was considered one of the best options for producing formal documents. Businesses valued it not because of speed, but because it delivered text that looked clean, uniform, and professional. For many offices, that consistency was more important than printing graphics or running high-volume jobs.

Legal letters

One of the most common uses was for legal letters. Contracts, agreements, and formal correspondence benefited from the machine’s sharp, typewriter-quality text. Companies wanted documents that looked polished and reliable, and the daisy wheel consistently delivered that look.

Receipts and billing

Some businesses also used these printers for receipts or billing statements. The impact mechanism ensured the text came out clear and permanent, which helped prevent disputes or modification. Even when carbon copies were used, the printer’s strong impressions transferred well across layers of paper.

Official office documents

Internal office paperwork—policy memos, HR documents, certifications, and procedural forms—were also regularly printed using daisy wheel units. The reliable output made it easy for businesses to maintain a consistent style across their official records. For many companies, the printer became a dependable everyday workhorse before the arrival of affordable laser printers.

Government & Legal Institutions

Government offices were among the longest users of the daisy wheel, mainly because of the emphasis on accuracy and document integrity. The Daisy Wheel Printer produced text that wasn’t just readable—it looked authoritative, which mattered for public records and legal materials.

Many government forms required exact spacing, aligned fields, and clean characters. Impact-based printing made this easier to achieve and ensured that each printed result met strict formatting standards. In court systems, administrative departments, and public service offices, the printer was often trusted for items such as summonses, certificates, licenses, and formal notifications.

In the legal world, the machine offered another benefit: the printed text left a physical impression on the page. This helped authenticate documents and made tampering more noticeable. Law offices, notary departments, and clerical teams dealing with official paperwork often preferred daisy wheel output for this reason alone. The consistency and durability of the print were simply difficult to match with early ink-based systems.

Archival & Authentication Needs

For archival work, the Daisy Wheel Printer provided something many early printers couldn’t—long-lasting, stable output. The text stayed sharp for years, resisted fading, and bonded well to the paper. This made the printer suitable for records that needed to remain readable long into the future.

Some libraries, banks, and institutional archives continued using daisy wheel printers because the documents produced didn’t deteriorate quickly. The deep, impact-driven impression also complemented verification printing workflows—any attempts to alter the text were easier to detect.

In environments that required both permanence and authenticity, the daisy wheel’s mechanical output offered a level of security and clarity that digital printing couldn’t guarantee at the time. Even as modern printers became faster and more flexible, a few specialized fields still found it valuable for ensuring stable, trustworthy documentation.

Daisy Wheel Applications by Industry

| Industry | Example Use | Reason for Using Daisy Wheel |

|---|---|---|

| Legal firms | Contracts, certifications | Permanent, tamper-resistant text |

| Government offices | Official notices, licenses | Clear, consistent formatting |

| Banking & finance | Statements, verification slips | Impact text ideal for multi-part forms |

| Archival institutions | Long-term records | Durable, stable output |

| Authentication units | Document verification | Physical imprint helps detect alterations |

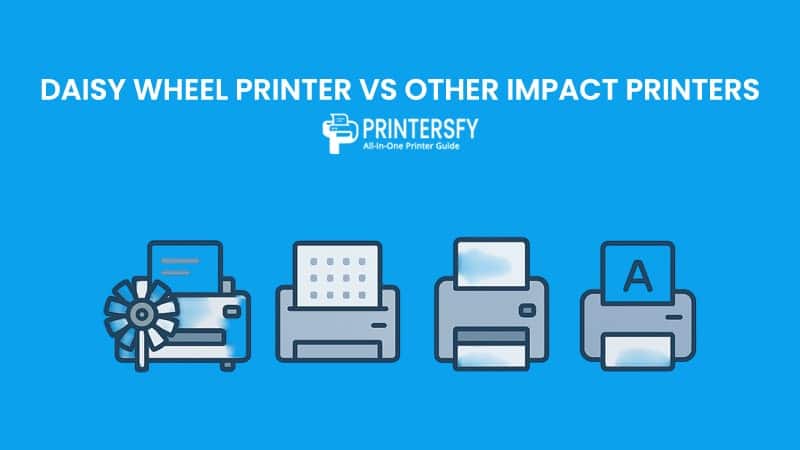

Comparison Daisy Wheel vs Other Impact Printers

Different impact printers were built for different purposes, and each one has its own strengths and weaknesses. The Daisy Wheel Printer stands out for text clarity, but it’s not the fastest or the most versatile. The table below highlights how it compares with other common impact-based technologies such as dot matrix, line printers, and character printers.

Daisy Wheel vs Dot Matrix vs Line Printer vs Character Printer

| Feature | Daisy Wheel Printer | Dot Matrix Printer | Line Printer | Character Printer |

|---|---|---|---|---|

| Print Quality | Very high, sharp text (letter-quality) | Low–medium, pin-based characters | Medium, block-style text | High for text, limited styles |

| Speed | Slow (10–75 cps) | Moderate to fast | Very fast (lines at a time) | Moderate |

| Noise | High mechanical impact | Noticeable but lower than daisy wheel | Loud | Moderate–high |

| Graphic Capability | None (text only) | Yes (basic graphics) | None | None |

| Cost | Moderate (wheel replacements needed) | Low–moderate | High | Moderate |

| Durability | Very durable | Durable but ribbons wear quickly | Very durable | Durable |

Conclusion

The Daisy Wheel Printer played an important role in shaping the expectations for high-quality text output during the early years of personal computing. Its mechanical precision, solid construction, and sharp letter-quality results made it a trusted tool for offices, legal institutions, and archival environments. While it lacks the speed and flexibility of modern printers, it excelled in areas where clarity and permanence mattered most.

Today, the technology stands as a reminder of an era when printing was more mechanical than digital. Its limitations eventually opened the door for inkjet and laser printers, but the influence of its clean, consistent output can still be seen in modern printing standards. Even as a vintage device, the Daisy Wheel Printer remains a notable chapter in the evolution of document production and professional text printing.

FAQs About Daisy Wheel Printer

What is the main purpose of a Daisy Wheel Printer?

A Daisy Wheel Printer is primarily designed for producing sharp, letter-quality text. It was widely used for documents that needed a clean, professional appearance, such as contracts, legal letters, certificates, and business correspondence.

Can a Daisy Wheel Printer print graphics or images?

No. Daisy wheel technology is strictly text-only. Each character is a fixed metal shape on the wheel, so the printer cannot form images, charts, or logos. This limitation is one of the main reasons the technology eventually faded as printing needs became more visual.

Why did offices prefer Daisy Wheel Printers in the past?

Offices appreciated their consistency and reliability. Unlike early dot matrix printers, the daisy wheel produced fully formed characters with excellent clarity. Businesses that required formal, professional text often chose these printers because of their dependable output.

Are Daisy Wheel Printers still used today?

Not widely. However, some specialized environments—like legal departments, archives, and authentication units—still use them for tasks that require permanent, tamper-resistant text impressions. Their impact printing style offers a level of durability that modern printers don’t always provide.

How does a Daisy Wheel Printer differ from a dot matrix printer?

A Daisy Wheel Printer prints characters using solid metal letterforms, resulting in very sharp text. Dot matrix printers, on the other hand, build characters from tiny pins, which makes the output more pixelated. Dot matrix printers are faster and capable of basic graphics, but their text clarity generally can’t match the daisy wheel.