Printers are often treated as background tools—quietly doing their job until the moment something goes wrong. A paper jam, streaked colors on an important presentation, or a blinking light that refuses to go away can suddenly remind us just how much we rely on them. Among the many printing technologies available today, the inkjet printer remains one of the most familiar and widely used, both at home and in small offices.

Despite the rise of alternatives like laser printers, inkjet technology has managed to hold its ground. Part of the reason is accessibility: inkjet printers are usually affordable to buy, compact enough to fit on a desk, and capable of producing detailed, vibrant prints. From family photos to business documents, they’re often the first choice for people who need a reliable “do-it-all” machine without spending too much upfront.

What makes this especially interesting is that inkjet printers have not only survived in a market filled with faster, higher-volume machines, but they’ve also continued to evolve. Features like refillable ink tanks, wireless printing, and improved print head designs have kept them relevant for everyday users. The balance between quality and convenience is what helps explain why inkjet printers remain so popular—even as laser printers dominate in high-volume office environments.

In this article, we’ll take a closer look at what an inkjet printer is, how it works, and why it continues to be a central part of printing technology today. By the end, you’ll have a clearer understanding of whether an inkjet printer fits your needs—or if another technology might suit you better.

What Is an Inkjet Printer?

An inkjet printer is a type of printing device that sprays tiny droplets of liquid ink directly onto paper to create an image or text. The name “inkjet” itself comes from the technology: controlled jets of ink that are fired in precise patterns, guided by digital instructions from a computer or mobile device. Unlike older impact printers, which physically strike ribbons against paper, inkjet printers deliver prints without mechanical contact, making them quieter and capable of producing much finer details.

From the outside, an inkjet printer might look simple: a compact box with a paper tray and a few buttons. Yet inside, it houses a system that combines engineering precision with chemical science. The heart of this technology lies in its print head, which contains hundreds—sometimes thousands—of nozzles capable of ejecting ink droplets smaller than the width of a human hair. This is why inkjet printers are known for their ability to produce high-resolution prints, often measured in dots per inch (DPI).

In practical terms, an inkjet printer allows you to transform digital files into physical copies with impressive accuracy. Whether it’s a sharp black-and-white document or a full-color photograph, inkjet technology reproduces details with vibrant tones and smooth gradients. Many home users appreciate this versatility: the same device can print homework assignments, greeting cards, family photos, or even basic labels.

Another reason inkjet printers remain popular is accessibility. They are generally more affordable upfront than laser printers, making them an attractive choice for students, households, and small businesses. While the long-term costs of ink can add up, the entry-level price and ease of use make them appealing for people who print in moderate volumes.

The global market for inkjet printers reflects this balance. According to IDC reports, inkjet shipments continue to account for a significant share of home and small office printers, particularly in regions like Southeast Asia where cost-sensitive buyers often prefer refillable ink tank models. This ongoing demand highlights how inkjet printers, despite being decades old as a technology, remain highly relevant in today’s digital-first world.

History and Evolution of Inkjet Printers

Early Concepts in the 1950s

The origins of inkjet printing can be traced back to the 1950s, when researchers began experimenting with the idea of spraying ink directly onto paper in controlled patterns. Unlike impact printers that relied on striking mechanisms, these early concepts aimed for quieter operation and higher resolution.

Breakthroughs in the 1970s and 1980s

Commercial development accelerated in the late 1970s and early 1980s. Canon introduced its Bubble Jet technology, which used heat to create bubbles that forced ink droplets through tiny nozzles. At the same time, Hewlett-Packard launched its DeskJet series, while Epson pioneered piezoelectric inkjet technology, offering greater control over droplet size and placement.

Mainstream Adoption in the 1990s

By the 1990s, inkjet printers had entered homes worldwide. Compact, relatively affordable, and capable of producing color prints, they quickly became a household staple. Compared to noisy dot matrix printers or expensive laser printers, inkjets offered an attractive balance of cost, quality, and convenience.

The Shift to Ink Tank Systems in the 2000s

A major turning point arrived with the introduction of ink tank systems. Instead of relying solely on small cartridges, models like Epson’s EcoTank and Canon’s MegaTank allowed users to refill large tanks, dramatically reducing the cost per page. This innovation solved one of the biggest criticisms of inkjet printers: high running costs.

Expansion into Professional and Industrial Use

Inkjet technology soon found applications beyond homes and offices. Large-format inkjet printers became standard in industries like graphic design, advertising, and architecture. Industrial variants were also adapted for fabric printing, packaging, and product labeling, proving the versatility of inkjet technology.

Today’s Inkjet Printers

Modern inkjet printers feature wireless connectivity, mobile printing, borderless photo printing, and advanced ink formulations. While laser printers dominate in speed and bulk output, inkjets remain the preferred choice where high-quality prints, affordability, and versatility are essential. Their evolution reflects a technology that has not only survived but adapted to new demands across decades.

Components of an Inkjet Printer

Before diving into the printing process, it’s useful to map out the physical systems that make an inkjet printer work. These components determine print quality, speed, reliability, and maintenance needs.

Ink Delivery System

Print Head

The print head is the core component that ejects ink droplets onto paper. It contains hundreds or thousands of microscopic nozzles and the actuation mechanism (thermal or piezoelectric). Thermal heads heat ink to create a vapor bubble that forces a droplet out; piezoelectric heads flex a crystal to push the droplet.

Design differences affect droplet size, DPI capability, durability, and cleaning frequency. In some consumer models the print head is built into the printer cartridge; in many prosumer or tank printers the head is fixed to the unit and cartridges are separate reservoirs.

Ink Cartridges

Ink supply comes as disposable cartridges or refillable tanks. Cartridges often contain small reservoirs and sometimes the print head; tanks (EcoTank, MegaTank) offer large-volume reservoirs that reduce running costs.

Ink chemistry matters: dye-based inks blend smoothly and produce vivid photos, while pigment inks provide sharper text and greater water resistance. Third-party cartridges can lower costs but may increase clogging risk or affect color profiling.

Paper Movement System

Paper Feed Mechanism

Feed rollers, separation pads, and sensors pick up each sheet, align it, and advance it past the print head at precise intervals. The feed motor and rollers must provide consistent motion to avoid banding, skew, or misregistration.

Paper Support & Edge Guides

Manual or automatic edge guides and thickness settings keep media aligned and prevent skewing. Proper alignment is a simple step that prevents many common print defects.

Output Tray

The output tray stacks finished pages and often includes a stop or ramp to avoid smudging. Some photo-capable printers use a rear straight-through path to keep heavy or glossy media flat.

Mechanical & Electrical Systems

Carriage & Belt

The carriage assembly carries the print head across the page on precision rails. A timing belt, driven by a motor, converts rotational motion into controlled linear movement. Wear, debris, or belt slack causes banding, ghosting, or uneven lines.

Stepper Motor

Stepper motors provide the micro-step control required for accurate carriage motion and paper advance. Their repeatability defines registration accuracy; failing motors lead to skew and inconsistent print placement.

Circuit Board

The mainboard (controller) interprets print jobs, times nozzle firings, controls motors/heaters, and reads sensor inputs. Firmware on the board manages color profiling, maintenance routines, and device communication.

Power Supply

A stable PSU supplies voltage for heaters (in thermal heads), motors, logic circuits, and sensors. Voltage instability or PSU failure can manifest as head heating errors, motor stalls, or intermittent faults.

Inkjet Printer Components: Functions, Common Issues, and Maintenance Guide

| Component | Primary Function | Common Issues | Typical Maintenance / Replacement |

|---|---|---|---|

| Print head | Ejects ink droplets to build image/text | Clogging, nozzle failure, misalignment | Regular cleaning cycles; head replacement if severely damaged |

| Ink cartridges / tanks | Stores and supplies ink | Empty/expired ink, dried nozzles, leakage | Refill/replace; use recommended inks; purge lines if needed |

| Paper feed rollers | Picks and advances paper | Slipping, wear, misfeeds | Clean rollers with isopropyl or replace when worn |

| Paper support & edge guides | Keeps media aligned | Skew, jams | Adjust guides; clear debris; check media specifications |

| Output tray / path | Protects and stacks prints | Smudging, bending of glossy media | Use straight-through path for thick media; avoid overstacking |

| Carriage & belt | Moves print head precisely | Belt wear, debris, looseness | Clean rails; tighten/replace belt if worn |

| Stepper motor | Precise motion control | Motor noise/stall, missed steps | Lubricate rails; replace motor if failure occurs |

| Circuit board (controller) | Controls timing and logic | Firmware bugs, component failure | Firmware updates; board replacement if defective |

| Power supply | Provides stable power | Voltage drops, overheating | Ensure stable mains; replace PSU if faulty |

How Does an Inkjet Printer Work?

An Inkjet Printer turns digital images into physical prints by coordinating software, tiny mechanical printer parts, and micro-scale ink droplets. At a high level the process is simple to describe: a digital file is translated into nozzle firings, the print head moves across the page, and ink lands on the paper.

The real detail — and what makes inkjet printing both powerful and fragile — is the precise timing and control behind each droplet. Below is a clear breakdown of that pipeline.

Digital Image to Data

Before a single droplet leaves the print head, the image must be converted into a format the printer can use. When you press “print,” the printer driver or the raster image processor (RIP) performs several tasks:

Print Head Movement

The driver sends rasterized data (a grid of pixels) to the printer controller. The controller schedules nozzle firings and calculates exact X/Y coordinates for each droplet.

The print head — mounted on a carriage — moves along a rail, usually driven by a timing belt and stepper motor. Motion is synchronized with nozzle firing so droplets hit precisely where they should.

Ink Ejection

Nozzles are fired in microsecond pulses. Each nozzle can deliver many droplets per second; the printer times these firings so that overlapping patterns of microscopic drops create continuous tones and sharp edges.

For multi-pass printing, the head makes several sweeps, laying down additional dots to increase density or correct banding.

Ink Propulsion Methods

Not all inkjets eject ink the same way. The two dominant mechanisms are thermal inkjet and piezoelectric inkjet, and each affects performance, ink chemistry, and maintenance.

Thermal Inkjet

Thermal inkjet uses tiny heater resistors inside each nozzle. A rapid electrical pulse heats a small volume of ink, forming a vapor bubble. When the bubble collapses, it forces a droplet out of the nozzle.

This method is simple and reliable for many consumer printers, but it requires inks that tolerate brief heat spikes (typically dye-based inks).

Piezoelectric Inkjet

Piezoelectric heads use a ceramic crystal that flexes when voltage is applied. The flex pushes ink out of the nozzle.

Piezoelectric systems give manufacturers more control over droplet size and placement, support a broader range of inks (including pigment-based formulations), and often last longer before requiring replacement. Many professional and industrial printers use piezoelectric technology.

Color Mixing (for color printers)

Color inkjet printers reproduce full-color images by combining tiny droplets of cyan, magenta, yellow, and black (CMYK). The printer lays down hundreds or thousands of microscopic dots per inch; the human eye blends them into continuous color and tone.

Color management plays a big role here. ICC profiles reconcile differences between your screen and the printer’s color gamut. Halftoning and dithering algorithms determine how to distribute droplets to simulate intermediate colors and gradients.

Higher print resolution (DPI) and smaller droplet volume improve detail and smoother gradients, but they also demand more precision in head movement and ink ejection timing.

Paper Advancement

After a strip is printed, the paper advances by a precisely controlled increment (often a fraction of a millimeter). Stepper motors and feed rollers synchronize this movement with the print head’s sweeps.

Paper type, thickness, and coating affect absorbency and drying time; those variables are why print drivers include media presets such as “plain paper,” “photo paper,” or “matte.”

Final Output

Once the image is fully deposited, the ink must dry or set. Dye inks absorb into the paper fibers; pigment inks sit more on the surface and may require more time to set. Some high-end or industrial printers include heated platens or instant-dry coatings to speed curing and prevent smudging.

The finished page then exits into the output tray, where stackers or anti-smudge ramps protect fresh prints.

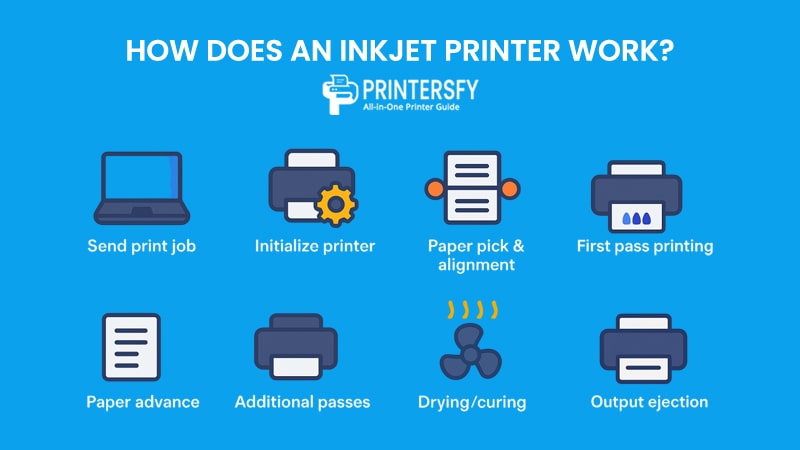

How the Inkjet Printing Process Works: Step-by-Step Explanation

| Step | Action | Technical detail | Why it matters |

|---|---|---|---|

| 1 | Send print job | Driver/RIP rasterizes image, applies color profile | Converts file into nozzle-ready instructions |

| 2 | Initialize printer | Head home position, clean cycles if needed | Ensures no clogged nozzles; primes ink flow |

| 3 | Paper pick & alignment | Feed rollers select and align sheet | Prevents skew and registration errors |

| 4 | First pass printing | Head fires nozzles while moving across page | Lays down initial dot pattern |

| 5 | Paper advance | Feed rollers move paper fractionally | Synchronizes next pass for layered printing |

| 6 | Additional passes | Head repeats sweeps to build density | Reduces banding and improves color blend |

| 7 | Drying/curing | Ink absorbs or is heated/coated | Prevents smearing and readies print for handling |

| 8 | Output ejection | Finished page stacked in tray | Keeps prints organized and protected |

Understanding this flow — from raster data to droplet deposition to drying — clarifies why inkjet printers excel at photo-quality, variable-data, and mixed-media printing.

It also explains their limitations: precise mechanics and tiny nozzles are vulnerable to clogging, and paper handling must be exact to maintain registration and prevent banding.

Types of Inkjet Printers

Inkjet printers may look similar from the outside, but what’s inside can be very different. The idea is always the same — tiny drops of ink sprayed onto paper — yet the way each printer does it, and the purpose it’s designed for, can vary a lot.

Some are built for simple everyday documents, others for photo perfection, and some for wide banners that stretch across a wall. Knowing these categories makes it easier to pick the right model for your own printing needs.

By Droplet Generation Technology

The heart of any inkjet printer lies in the way it forms and controls ink droplets. Broadly, this can be divided into Continuous Inkjet (CIJ) and Drop-on-Demand (DOD).

Continuous Inkjet (CIJ)

Continuous Inkjet was one of the earliest inkjet methods. Ink is pumped at high pressure through a nozzle, creating a continuous stream of droplets. Electrostatic fields then deflect selected droplets toward the paper while others are recycled back into the reservoir.

CIJ printers are not common in home or office environments because they are complex and expensive. Instead, they dominate industrial uses like date coding on packaging, barcoding, and printing directly onto non-porous materials such as glass, plastic, or metal. They offer high speed, excellent adhesion, and the ability to use solvent-based inks.

Drop-on-Demand (DOD)

Drop-on-Demand is the standard approach for consumer and office inkjet printers. Here, ink droplets are only generated when required — eliminating the recycling mechanism used in CIJ and allowing more compact designs. DOD has two primary implementations:

Thermal Inkjet

Thermal inkjet relies on micro-heaters inside each nozzle. A rapid pulse vaporizes ink, creating a bubble that pushes a droplet onto the paper. Hewlett-Packard (HP), Canon, and some Lexmark printers use this method.

It’s cost-effective and well-suited for dye-based inks, making it common in low- to mid-range devices. However, repeated heating and cooling can wear out print heads more quickly compared to piezoelectric systems.

Piezoelectric Inkjet

Piezoelectric inkjet replaces heat with a piezoelectric crystal. When voltage is applied, the crystal flexes, squeezing ink out of the nozzle.

Epson pioneered this method, which offers longer-lasting print heads, finer control over droplet size, and compatibility with a wider range of ink formulations — including pigment and specialty inks. For professional and industrial users, piezoelectric technology is often the gold standard.

By Functionality and Type

Inkjet printers also differ in their intended use case — from basic single-purpose devices to versatile multifunction units.

Single-Function Inkjet Printers

These are dedicated to printing only. They tend to be more compact, less expensive, and straightforward.

Users who don’t need scanning, copying, or faxing often choose these models. While stripped-down in features, single-function inkjets can deliver excellent print quality for documents and photos.

All-in-One (AIO) Printers

All-in-One printers integrate printing, scanning, copying, and often faxing into a single device. They dominate the home and office market because they save space and money compared to buying separate machines.

AIOs vary widely in speed, print quality, and ink system design, but they are usually optimized for general-purpose tasks rather than specialized professional output.

Tank Printers

Tank printers, also known as ink tank printers or refillable inkjet printers, replace disposable cartridges with large, refillable reservoirs. Introduced by Epson’s EcoTank and later adopted by Canon and HP, this system dramatically reduces cost per page.

Tank printers are especially popular in regions where printing volume is high, such as schools, small businesses, and print shops. While the upfront purchase price is higher, ongoing operating costs are much lower.

By Application

Certain inkjet printers are designed for specialized output needs.

Photo Inkjet Printers

Photo printers focus on producing lab-quality prints with high color accuracy and detail. They often use more than four inks (such as light cyan, light magenta, gray, or red/blue) to achieve smoother gradients and broader color gamuts.

High-end models support borderless printing and specialized photo papers. Enthusiasts and professionals choose them for printing photographs, art reproductions, or portfolios.

Large-Format Printers

Large-format or wide-format inkjets handle media sizes well beyond the standard A4 or letter sheets. They can print banners, posters, architectural blueprints, or signage up to several meters wide.

These printers use roll-fed media and advanced color management systems. In industries like advertising, engineering, and photography, large-format printers are indispensable.

Types of Inkjet Printers and Their Key Features Compared

| Category | Subtype | Key Features | Best Use Case |

|---|---|---|---|

| By Droplet Tech | Continuous Inkjet (CIJ) | Continuous ink stream, electrostatic deflection, solvent inks | Industrial coding, printing on packaging, non-porous materials |

| By Droplet Tech | Thermal Inkjet (DOD) | Uses heat to form vapor bubble, cost-effective, cartridge-based | Home and office documents, general-purpose printing |

| By Droplet Tech | Piezoelectric Inkjet (DOD) | Crystal flexes to eject ink, supports pigment inks, durable heads | Professional, industrial, and high-resolution printing |

| By Function | Single-Function Inkjet | Compact, print-only device | Basic printing at home or office |

| By Function | All-in-One (AIO) | Print, scan, copy, fax | Versatile home/office use |

| By Function | Tank Printers | Refillable reservoirs, low cost per page | High-volume printing, schools, businesses |

| By Application | Photo Inkjet Printers | Expanded color sets, high detail | Photography, art reproduction |

| By Application | Large-Format Printers | Prints on wide media rolls, color management | Posters, signage, blueprints, commercial graphics |

By breaking down inkjet printers into these categories, it becomes clear that “inkjet” is a broad label covering everything from a $70 desktop printer to a $20,000 large-format plotter.

Choosing the right model depends on balancing functionality, long-term costs, and the intended application.

Popular Inkjet Printer Brands and Models

Over the years, a few key manufacturers have dominated the market, each with their own unique approach to design, ink delivery, and user experience.

Some prioritize affordability, while others focus on photo quality or long-term efficiency. Let’s break down the most recognized names in the inkjet world and highlight what makes their models stand out.

Epson EcoTank Series

Epson has become almost synonymous with “ink tank printing.” The EcoTank series replaced the traditional cartridge model with refillable tanks, drastically lowering cost per page. This approach appeals to home offices and small businesses that want to avoid the frustration of frequently changing expensive cartridges.

Epson also earns praise for its sharp photo quality, especially in its higher-end models designed for photography enthusiasts.

Canon PIXMA Line

Canon’s PIXMA printers strike a balance between everyday usability and excellent photo reproduction. Known for vibrant colors and fine detail, they’re a favorite among designers, students, and families who value sharp image printing.

Many PIXMA models also include wireless features and compact designs, making them practical for small spaces without sacrificing output quality.

HP DeskJet and OfficeJet

HP’s DeskJet and OfficeJet lines remain go-to options for casual users and small offices. DeskJet focuses on affordability and ease of use, while OfficeJet adds more business-oriented features like higher paper capacity and faster speeds.

HP also invests heavily in smart app integration, allowing users to print directly from cloud storage or mobile devices with minimal hassle.

Brother Inkjet Printers

While Brother is often associated with laser machines, its inkjet lineup shouldn’t be overlooked. Brother inkjets typically emphasize reliability and balanced performance at reasonable prices.

Their all-in-one models, in particular, are well-suited for mixed home-and-office environments where scanning, copying, and occasional high-quality color printing are needed.

Popular Inkjet Printer Models and Brand Comparisons

| Brand | Signature Model Line | Key Strengths | Best For |

|---|---|---|---|

| Epson | EcoTank | Ultra-low running costs, refillable tanks, excellent photo quality | High-volume home/office use |

| Canon | PIXMA | Vibrant colors, great for images, compact designs | Students, families, designers |

| HP | DeskJet / OfficeJet | Affordable entry-level, smart printing features, business-ready options | Home users, small offices |

| Brother | All-in-One Inkjet | Reliable, versatile, solid performance at fair prices | Mixed home-office environments |

Advantages of Inkjet Printers

Every technology has its strong points, and inkjet printers are no exception. They continue to dominate home and small office markets not just because they’re affordable, but also because they deliver print quality and flexibility that other printer types often struggle to match.

Let’s look deeper into the key advantages that make inkjets a favorite for millions of users.

High-Quality & Vibrant Prints

Photo & Graphics

One of the strongest benefits of inkjet printers is their ability to produce rich, colorful, and high-resolution images. Whether it’s a family photograph, a school project, or a graphic-heavy presentation, inkjets excel at capturing subtle shades and gradients. This makes them the go-to option for photographers, designers, and anyone who values image accuracy.

Fine Details

Inkjet printers can produce extremely fine lines and crisp text, even on standard paper. Thanks to their ability to spray very small ink droplets, details like small fonts or intricate patterns come out sharper compared to most budget-friendly laser printers. For tasks that demand precision, such as printing charts, invitations, or marketing materials, this fine-detail capability is invaluable.

Affordability & Cost-Effectiveness

Low Initial Cost

One of the first things buyers notice is how affordable inkjet printers are. Entry-level models are often priced much lower than comparable laser printers, making them accessible to students, families, or small businesses on a budget.

Cost-Effective for Small Runs

Inkjets shine when it comes to short print jobs. Printing 10–20 pages of text or a handful of color documents doesn’t require the same upfront investment as a laser. For households or offices that print occasionally rather than in bulk, this makes inkjets a smart and economical choice.

Versatility & Flexibility

Diverse Media

Unlike many laser printers, inkjets can handle a wide range of paper types and sizes. From glossy photo paper to labels, cards, and even specialty media like iron-on transfers, inkjets adapt easily. This flexibility is a huge advantage for creative projects or businesses that want to offer customized materials.

Variable Data Printing

Inkjet technology also allows for highly variable printing, meaning each page in a batch can include unique information without slowing down the process. This is particularly useful for personalized mailers, invitations, or promotional materials where every piece needs to look slightly different.

Operational Advantages

Compact & Lightweight

Most inkjet printers are designed with home and small-office users in mind, so they’re typically lightweight and easy to fit into tight spaces. Even multifunction inkjet printers with scanning and copying features remain compact compared to bulkier laser machines.

Quiet Operation

Unlike the whirring and clunking sounds of some laser or dot matrix printers, inkjets operate quietly. This makes them ideal for home offices, libraries, or shared spaces where noise can be distracting.

Fast Turnaround

For single-page or small-batch jobs, inkjets often feel faster because there’s little to no warm-up time. You hit print, and the first page is out almost instantly — a convenience that users appreciate for quick tasks.

Energy Efficient

Inkjets generally consume less power than their laser counterparts. Since they don’t rely on heating elements to fuse toner, they require less energy during operation, making them both eco-friendly and cost-saving in the long run.

Disadvantages of Inkjet Printers

While inkjet printers offer excellent print quality and versatility, they also come with trade-offs that buyers need to weigh carefully. From expensive consumables to performance limitations, these drawbacks explain why many businesses or high-volume users still prefer alternatives like laser printers.

Cost & Maintenance

Expensive Ink Cartridges

One of the biggest complaints about inkjet printers is the high price of replacement ink cartridges. In many cases, the cost of a full set of cartridges can equal — or even exceed — the price of the printer itself. Users on forums like r/printers frequently point out how frustrating it is to spend more on ink than on the hardware.

High Cost Per Page

Compared to laser printers, the cost per page for inkjets is much higher. For example, printing a full-color document can cost several times more with inkjets due to the limited yield of cartridges. This makes them less ideal for offices or students who need to print hundreds of pages regularly.

Ink Clogging

Because ink is liquid-based, cartridges can dry out when the printer is unused for weeks. This often leads to clogged print heads, which not only cause streaky or incomplete prints but may also require time-consuming cleaning cycles or professional servicing.

Performance & Quality

Slow Printing Speed

Inkjet printers are generally slower than laser printers, particularly for bulk jobs. Printing a lengthy report or a stack of documents can feel inefficient when compared to the rapid page-per-minute speed that laser printers deliver.

Prone to Smudging

Fresh ink on the page can easily smudge if touched too quickly. On glossy or low-quality paper, smearing is even more common. For anyone printing professional reports, this can be a frustrating limitation.

Limited Durability & Lifespan

Most inkjet printers are not built for heavy-duty use. Their plastic construction and lightweight parts make them less durable than office-grade laser printers. Over time, frequent use can lead to wear and tear, shortening the machine’s overall lifespan.

Ink Bleeding

Another common issue is ink bleeding, where colors spread slightly on the paper fibers. This reduces sharpness, especially on regular copy paper, and can make text or graphics look less crisp.

Suitability for Specific Tasks

Not for High Volume

If you need to print thousands of pages every month, inkjets are rarely the right choice. Their limited paper handling capacity, slower speeds, and higher operating costs make them inefficient for large-scale printing environments.

Environmental Sensitivity

Inkjet performance can be affected by humidity and temperature. For instance, high humidity can cause paper to warp and absorb more ink, leading to blurry prints. Meanwhile, very dry conditions can accelerate ink drying inside cartridges, increasing the risk of clogging.

Environmental Impact of Inkjet Printers

Like any technology, inkjet printers affect the environment in both positive and negative ways. While they are more energy-efficient compared to some alternatives, concerns remain about cartridge waste and long-term sustainability. Understanding their environmental footprint helps users make more eco-conscious choices.

Energy Consumption and Efficiency

One of the strengths of inkjet printers is their relatively low energy usage. Unlike laser printers, which rely on heat to fuse toner onto paper, inkjets spray ink directly. This means they don’t require a warm-up period and typically consume less electricity during operation.

For households or small offices that only print occasionally, the energy savings can add up over time. Many modern inkjet models also include eco-modes that reduce power draw even further, reinforcing their reputation as an eco-friendly printer option.

Cartridge Recycling and Waste Reduction

The major environmental drawback of inkjet printers is cartridge waste. Millions of plastic ink cartridges end up in landfills each year, and since many are made with mixed plastics and residual ink, they’re difficult to recycle. Some manufacturers, like HP and Canon, have introduced cartridge return and recycling programs to reduce this problem.

In addition, the rise of ink tank systems has helped minimize waste by allowing users to refill larger reservoirs instead of constantly replacing small cartridges. Choosing printers designed for refillable ink systems is one of the most effective ways to cut down on unnecessary plastic waste.

Inkjet Printing in a Sustainable Future

Looking ahead, the inkjet industry is moving toward greener solutions. From bio-based inks to printers designed with recyclable materials, manufacturers are responding to growing demand for sustainable printing. For example, Epson has highlighted the reduced carbon footprint of its EcoTank series compared to traditional cartridge printers.

While inkjets are not perfect, the trend shows that with responsible cartridge recycling and thoughtful purchasing decisions, they can fit into a more sustainable printing ecosystem. For environmentally conscious users, selecting an inkjet printer with refillable tanks, low standby power consumption, and certified recycling programs makes a meaningful difference.

Inkjet Printer Compared with Other Printing Technologies

Inkjet printers are popular because they balance quality, cost, and convenience. But they don’t exist in isolation — several other printing technologies compete in different markets. Comparing inkjets with alternatives like laser, dot matrix, and even 3D printers helps highlight where they shine and where they fall short.

Inkjet vs Laser Printers

When people think about choosing between inkjet vs laser printers, the debate often centers on color quality versus speed and volume. Inkjet printers produce sharper images and richer colors, making them ideal for photos, graphics, and documents where detail matters. Laser printers, on the other hand, are built for efficiency. They can churn out dozens of pages per minute and handle large print runs without slowing down.

Cost per page is another key difference. While inkjet printers usually have a lower upfront cost, their cartridges run out quickly and are expensive to replace. Laser printers require pricier toner cartridges, but those cartridges last far longer, driving down the long-term cost per page. In short, inkjets work best as a home printer or for light office use, while lasers dominate in environments where volume and speed are the priority.

Inkjet vs Dot Matrix (Impact Printers)

Dot matrix printers might seem outdated, but they’re still used in certain niches. The main difference between inkjet vs dot matrix printers is the technology: inkjets spray liquid ink onto paper, while dot matrix printers use an impact mechanism with pins striking an ink ribbon.

Dot matrix printers are noisy and produce low-resolution output, but they have unique strengths. Because they can print multiple copies using carbon paper, they remain popular for invoices, receipts, and shipping forms. Inkjets, with their quiet operation and superior quality, are better suited for everyday documents and images. This makes dot matrix printers a specialized tool, while inkjets cover a broader range of needs.

Inkjet vs Solid Ink Printers

Solid ink printers, most famously developed by Xerox, use wax-like ink blocks that are melted and applied to paper. The result is vibrant, saturated color with minimal waste. Compared to inkjets, solid ink devices produce high-quality graphics and are often praised as an eco-friendly option because of their reduced packaging waste.

However, solid ink printers never became mainstream. They tend to be bulky, require significant warm-up time, and have limited manufacturer support today. In contrast, inkjet printers remain compact, widely available, and cost-effective for both home and office users. For most buyers, the familiarity and flexibility of inkjets outweigh the niche advantages of solid ink printers.

Inkjet vs Liquid Ink Printers

At first glance, liquid ink printers might sound like a completely different technology, but in reality, the term often overlaps with inkjets. Both use liquid-based inks, though the distinction usually refers to the method of delivery. Inkjets rely on precise nozzles to spray micro-droplets, while some liquid ink systems use continuous flow mechanisms more common in industrial settings.

The overlap in terminology can cause confusion. For everyday users, an inkjet printer is essentially a liquid ink printer designed for consumer or office use. Specialized industrial machines, however, may fall under the broader “liquid ink” category, serving packaging, labeling, or high-volume commercial printing.

Inkjet vs 3D Printers

Comparing inkjet printers to 3D printers highlights just how diverse printing technologies have become. Traditional inkjets deal with two-dimensional documents and images, while 3D printers build objects layer by layer using materials like resin, plastic, or even metal.

Interestingly, some 3D printing technologies borrow principles from inkjets, especially the idea of depositing material in precise droplets. But the applications are worlds apart: inkjets are designed for paper-based communication, while 3D printers belong to the realm of manufacturing and prototyping. It’s less about competition and more about serving entirely different needs.

Inkjet vs Specialty Printers

Specialty printers focus on specific applications where inkjets may not be the best fit. For example:

- Label printers are optimized for adhesive-backed media.

- Sublimation printers transfer dye into materials like fabric, mugs, or metal plates, making them popular for personalized products.

- Thermal printers create receipts or shipping labels quickly and without ink, relying on heat-sensitive paper.

Compared to these, inkjets are true general-purpose printers. They may not match the efficiency of thermal printers or the permanence of sublimation output, but they provide the flexibility to handle everyday tasks — from printing homework assignments to producing a glossy photo.

Inkjet Printers Compared to Other Printer Types: Pros and Cons

| Printer Type | Strengths | Weaknesses | Best Use Case |

|---|---|---|---|

| Inkjet Printers | High-quality color, detailed images, compact size, versatile media support | Expensive ink cartridges, slower for high-volume printing | Home use, photo printing, small office tasks |

| Laser Printers | Fast printing speed, durable, low cost per page in the long run | Higher upfront cost, less vibrant color quality | Offices, schools, high-volume document printing |

| Dot Matrix Printers | Carbon-copy printing, durable in harsh environments, low running cost | Noisy, low resolution, outdated technology | Invoices, receipts, shipping documents |

| Solid Ink Printers | Vibrant color, less packaging waste, eco-friendly approach | Bulky, slow warm-up, declining market support | Graphic-intensive documents (niche use) |

| Liquid Ink Printers | Continuous ink systems for industrial applications | Larger footprint, higher maintenance for specialized setups | Industrial packaging & labeling |

| 3D Printers | Creates 3D objects, layer-by-layer precision, prototyping capabilities | Expensive, not for documents, slower production times | Manufacturing, product design, prototyping |

| Specialty Printers | Tailored outputs (labels, sublimation, thermal receipts) | Limited flexibility outside their niche | Retail, personalization, logistics |

Conclusion

Inkjet printers remain one of the most versatile and widely used printing technologies today. They excel in producing high-quality prints with sharp details and vibrant colors, making them suitable for both home and professional use. While they come with some drawbacks—like higher ink costs and slower speeds compared to laser printers—their strengths in print quality and flexibility often outweigh these limitations.

Even in the age of fast laser printers and specialized printing technologies, inkjet printers hold a strong position because of their ability to handle diverse media, affordable entry price, and superior photo printing. For users who value precision, portability, and color accuracy, inkjet printers continue to be an essential tool.

FAQs About Inkjet Printers

What is meant by inkjet printer?

An inkjet printer is a type of printer that sprays tiny droplets of liquid ink directly onto paper to create an image or text.

What is the difference between an inkjet printer and a regular printer?

The term “regular printer” usually refers to common types like laser or dot matrix. Inkjet printers are defined by their liquid ink technology, which sets them apart.

How do you know if your printer is inkjet?

Check the cartridges—if your printer uses liquid ink cartridges instead of toner, it’s an inkjet printer.

How often do inkjet cartridges need replacing?

Replacement depends on usage, but typically every few weeks for heavy printing or every few months for light use.

How many years does an inkjet printer last?

Most inkjet printers last between 3–5 years with proper care, though lifespan can vary based on maintenance and usage frequency.