Have you ever noticed how most home printers either run out of ink too quickly or leave colors looking flat? That gap in print quality and efficiency is where solid ink printers came in. Instead of relying on liquid cartridges or powdered toner, these machines use colorful wax-like sticks that melt during printing to produce bold, saturated results.

Solid ink printers once captured attention for their eco-friendly design, consistent color output, and relatively simple maintenance. Yet today, many people wonder: what exactly are solid ink printers, how do they work, and are they still relevant in 2025?

This article explores the full picture—from the definition and technology behind them to their real-world benefits, drawbacks, and alternatives—so you’ll know whether they fit your printing needs.

What Are Solid Ink Printers? (Definition and Basic Concept)

A solid ink printer is a type of printer that uses solid blocks of ink instead of liquid cartridges or powdered toner. These blocks look like colorful wax sticks. When you insert them into the machine, they are melted and transferred onto paper, producing rich, vibrant prints.

The concept was first developed by Tektronix in the late 1980s and later taken over by Xerox, which became the only major manufacturer of solid ink printers. At the time, this technology was seen as a breakthrough because it simplified printing—users didn’t have to deal with messy cartridges, leaking liquid ink, or bulky toner units.

Unlike inkjet printers, which spray droplets of liquid ink directly onto paper, or laser printers, which use toner powder fused by heat, solid ink printers rely on a more direct melting process. The ink sticks are heated, turned into liquid, and then applied to a drum before being pressed onto the page. This gives them a unique advantage in terms of color vibrancy and consistency, particularly for graphics-heavy documents.

In short, solid ink printers combine aspects of efficiency, sustainability, and print quality in a way that made them appealing to offices, schools, and businesses that needed dependable, high-quality output without the hassle of frequent cartridge replacements.

How Solid Ink Technology Works

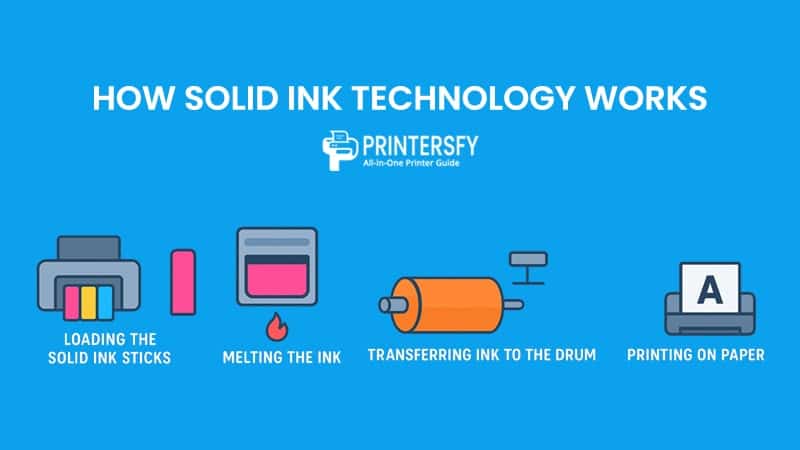

The inner workings of a solid ink printer may sound complex, but the process is surprisingly straightforward once broken down. Unlike inkjet printers that spray liquid ink directly onto paper or laser printers that fuse toner powder using heat, solid ink printers use a unique melting-and-transfer system. The ink starts as a solid block, is melted into liquid, and then applied to paper through an imaging drum.

This step-by-step process ensures vibrant results with minimal waste. Let’s look closer at each stage to understand how the technology delivers such consistent output.

Loading the Solid Ink Sticks

The process begins when users insert the solid ink sticks into the printer. Each stick is molded in a way that fits only its designated slot, whether cyan, magenta, yellow, or black. This design prevents mistakes and makes reloading easier than changing traditional cartridges. Many users appreciate that solid ink requires less packaging, which means fewer materials end up in the trash.

Unlike liquid cartridges, which can dry out if not used, solid ink sticks remain stable until they’re melted. That makes them convenient for offices where the printer might sit idle for days or weeks without causing ink waste.

Melting the Ink

Once the sticks are loaded, the printer activates its heating system. The solid ink is melted at high temperatures, turning into a smooth liquid ready for printing. This process is carefully calibrated so the ink maintains the right viscosity, ensuring even flow and accurate color reproduction.

The melting step takes a bit of time—often a few minutes—before the printer is ready to produce the first page. While some users see this as a drawback compared to instant-start inkjets, others accept it as a fair trade for the superior print quality and lower long-term waste.

Transferring Ink to the Drum

After the ink is melted, it is sprayed onto a heated imaging drum. This drum serves as a temporary canvas where the image or text is formed before being applied to the paper. Precision printheads control the exact placement of the liquid ink on the drum, ensuring sharp details and consistent colors.

The use of a drum also helps stabilize the process. By separating the image formation from the paper itself, the printer reduces alignment issues and produces more reliable results, especially for graphics-heavy prints.

Printing on Paper

In the final step, the heated drum rolls against a sheet of paper, transferring the image in one smooth motion. As soon as the liquid ink touches the cooler paper, it solidifies almost instantly. This quick cooling ensures the colors remain vibrant and prevents smudging.

Because the ink rests slightly on top of the paper’s surface instead of soaking in, prints often look glossier and more vivid than those produced by inkjet printers. This unique finish is one of the reasons solid ink printers became popular for marketing materials, presentations, and any document where strong visual impact was important.

How Do Solid Ink Printers Work? Step-by-Step Process

| Step | Process | Explanation |

|---|---|---|

| 1 | Loading the Solid Ink Sticks | Users insert wax-like ink sticks into color-coded slots (CMYK). The unique shapes prevent mistakes and simplify maintenance. |

| 2 | Melting the Ink | The printer heats the sticks until they liquefy. This prepares the ink for smooth flow and accurate color reproduction. |

| 3 | Transferring to the Drum | A heated imaging drum receives the melted ink. Precision printheads place the design or text on the drum surface. |

| 4 | Printing on Paper | The drum presses the liquid design onto paper, where the ink instantly cools and solidifies, producing vibrant, sharp prints. |

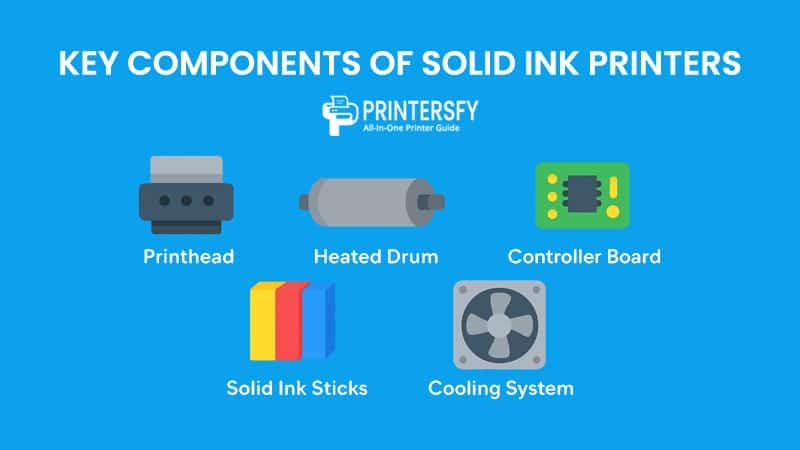

Key Components of Solid Ink Printers

Every solid ink printer relies on a set of carefully designed components that work together to transform colorful wax-like sticks into high-quality prints. Each part contributes to the efficiency and reliability of the overall process, from melting the ink to transferring it onto paper. While the system may seem simple on the surface, understanding the role of each component reveals why these printers stand out in certain applications.

These printer components are not only mechanical but also electronic, ensuring that heating, cooling, and precise ink placement happen seamlessly. For users, knowing these parts provides insight into maintenance needs, performance strengths, and why solid ink printers differ from their inkjet and laser counterparts.

Printhead

The printhead is the precision element that sprays melted ink onto the imaging drum. It operates with extreme accuracy, placing droplets exactly where they need to go to form sharp text and detailed images. This component is central to maintaining the printer’s reputation for vibrant, consistent color output. Without a reliable printhead, the entire printing process would lose its precision.

Unlike inkjet printheads, which are prone to clogging when liquid ink dries out, solid ink printheads deal exclusively with melted wax ink. This reduces the risk of frequent blockages, making them easier to maintain. However, because the ink must stay at the right viscosity during printing, the printhead still requires occasional calibration to deliver optimal results.

Heated Drum

At the core of every solid ink printer lies the heated imaging drum. This rotating drum acts as an intermediary surface that receives the melted ink before transferring it onto paper. It must stay at a carefully controlled temperature to keep the ink in liquid form long enough to create a clean, well-defined image.

The use of a drum offers several benefits. By forming the design on the drum rather than directly on paper, the printer reduces alignment issues and ensures a smooth, consistent transfer. This results in prints that look sharper and more uniform, especially for documents containing heavy graphics or solid color blocks.

Solid Ink Sticks

The solid ink sticks themselves are what make this printer unique. Shaped like small, colorful blocks, they are loaded into dedicated slots for cyan, magenta, yellow, and black. Their compact, cartridge-free design minimizes packaging waste, which made them appealing to businesses looking for eco-friendly solutions.

In addition to being easy to handle, the ink sticks offer high efficiency. Because they are consumed almost entirely during printing, there is little leftover waste. Unlike liquid cartridges that often leave behind unused ink, solid sticks deliver nearly 100% utilization, which helps reduce operating costs over time.

Controller Board

Behind the physical components lies the controller board, which serves as the printer’s brain. It manages the heating system, regulates the timing of the printhead, and ensures the imaging drum and paper feed are perfectly synchronized. Without this electronic coordination, the process would result in misaligned images or uneven color distribution.

For businesses, the reliability of the controller board translates into predictable performance. It allows solid ink printers to handle complex print jobs while maintaining consistent quality, making them a practical choice for offices that demand both speed and precision.

Cooling System

The final step in the process depends on the printer’s cooling system. Once the melted ink is transferred onto the paper, it must solidify quickly to prevent smudges or blurring. Cooling fans and carefully designed airflow ensure the ink hardens almost instantly as the sheet exits the machine.

This rapid cooling not only stabilizes the print but also contributes to its distinctive look. Because the ink solidifies on the surface of the paper rather than soaking into the fibers, the finished output has a glossy, vivid appearance. This is one of the reasons solid ink printers became popular for producing marketing materials, presentations, and other visually demanding documents.

Typical Specifications of Solid Ink Printers

| Feature | Typical Value | Explanation |

|---|---|---|

| Print Speed | 20–40 pages per minute (ppm) | Suitable for small to medium offices; slower than high-end laser models but consistent for graphics. |

| Print Resolution | Up to 2400 dpi | Produces sharp text and vibrant, saturated colors—ideal for images and marketing materials. |

| Warm-Up Time | 3–5 minutes | The printer requires heating before first use, which can delay quick print jobs. |

| Monthly Duty Cycle | 85,000–120,000 pages | Designed to handle heavy office workloads while maintaining quality. |

| Media Support | Standard paper, labels, transparencies, envelopes | Flexible media handling compared to many inkjet printers. |

| Ink Yield | Around 10,000 pages per set of sticks | Higher efficiency than liquid cartridges, with minimal packaging waste. |

| Energy Use | Higher during warm-up, moderate while printing | Heating system consumes noticeable energy at startup, but stabilizes during operation. |

Benefits of Solid Ink Printers

While solid ink printers never became as mainstream as inkjet or laser models, they offered a unique set of advantages that made them appealing for specific users. From exceptional print quality to eco-friendly operation, these benefits positioned solid ink technology as a forward-thinking alternative during its peak years.

Understanding these strengths helps explain why many businesses and organizations once adopted solid ink printers, and why some still consider them useful today.

High Print Quality and Color Vibrancy

One of the most noticeable strengths of solid ink printers is their ability to produce rich, vibrant prints. Because the ink sits on the surface of the paper rather than soaking in, colors appear more saturated and glossy compared to most inkjet output. This made the technology particularly attractive for companies printing marketing materials, graphics, or presentations where visual impact was essential.

In practice, solid ink printers were often compared to high-end inkjets in terms of output quality, but with greater consistency across large print runs. For instance, a batch of brochures printed with solid ink maintained the same level of brightness and sharpness from the first page to the last, something that cheaper inkjets often struggled to achieve.

Environmentally Friendly Printing

Another standout benefit is the eco-friendly design. Unlike traditional ink cartridges or toner units, solid ink sticks are compact and require minimal packaging. That means less plastic waste ends up in landfills, aligning with sustainability goals that many businesses prioritize today.

Additionally, nearly all of the solid ink stick is consumed during printing. There is no leftover liquid drying inside a cartridge or toner dust wasted in a drum. This high utilization rate further reduces waste, making solid ink printers a more environmentally conscious choice than most other printer types of their era.

Cost Efficiency in the Long Run

Although solid ink printers often carried a higher purchase price upfront, their long-term operating costs could be lower. Each stick of solid ink produced thousands of pages, often at a lower cost per page compared to liquid cartridges. This efficiency made them a cost-effective solution for offices with regular, high-volume printing needs.

For example, businesses producing colorful newsletters or training manuals could save money by using solid ink printers rather than inkjets, which consumed more expensive cartridges. The lower waste factor also meant less money spent on replacements and disposables.

Compact and Simple Design

Solid ink printers were also appreciated for their relatively straightforward construction. With fewer moving parts than complex laser printers, they were less prone to mechanical breakdowns. The absence of bulky cartridges and separate imaging drums simplified both the design and the user experience.

This compactness made them especially useful in offices where space was limited. A single device could handle daily workloads without taking up as much desk space as comparable multifunction printers. For many users, the ease of loading ink sticks and the simplicity of the design were major time-savers.

Drawbacks of Solid Ink Printers

Even though solid ink printers offered several benefits, they were not without limitations. These drawbacks ultimately played a big role in preventing the technology from becoming mainstream. For some users, the issues were minor inconveniences, while for others they were deal-breakers that pushed them toward inkjet or laser alternatives.

By looking closely at these disadvantages, it becomes clear why solid ink printers peaked in popularity during the 2000s but slowly declined in adoption afterward.

Warm-Up Time and Energy Use

One of the most common complaints about solid ink printers is their warm-up time. Since the ink sticks need to be melted before printing can begin, the machine often takes three to five minutes to get ready. For users who needed quick, one-page printouts on demand, this delay felt frustrating compared to instant-on inkjet printers.

Energy consumption is another factor tied to the warm-up process. Heating the solid ink requires significant electricity, especially during startup. Although power use levels off once the printer is running, the initial surge made these printers less energy-efficient than some modern laser or ink tank models. For organizations focused on reducing electricity costs, this became a notable drawback.

Print Durability and Smudge Issues

While solid ink produced bright, glossy colors, the prints were not always as durable as laser output. Because the ink sits on top of the paper rather than soaking in or being fused at a molecular level, it was more susceptible to scratching or smudging under pressure. Over time, documents handled frequently could show wear that toner-based prints would have resisted.

Heat sensitivity was another concern. If prints were exposed to high temperatures—such as being left inside a hot car—the ink could soften or even slightly re-melt, causing distortion. This made solid ink printers less practical for producing documents that needed to last in tough environments.

Higher Initial Cost and Limited Market

Another drawback was the higher purchase price. Solid ink printers often cost more upfront than comparable inkjets or entry-level laser models. While the cost per page was competitive, the initial expense discouraged budget-conscious buyers, especially home users and small offices.

In addition, the market for solid ink printers was limited. After Xerox acquired the technology from Tektronix, they became the only significant producer of these machines. With fewer models and limited competition, buyers had fewer choices and often paid more compared to the diverse range of inkjet and laser printers available.

Noise and Odor Considerations

Some users also reported noise and odor during operation. The heating process sometimes produced a faint waxy smell, which could be noticeable in small office spaces. While not harmful, it was distracting for people working in close proximity to the printer.

Noise was another factor, particularly during warm-up and melting cycles. Compared to the quiet operation of many inkjet models, solid ink printers could sound mechanical and intrusive. For offices prioritizing a silent environment, this characteristic made them less appealing.

Solid Ink Printers vs. Other Printer Types

To better understand the position of solid ink printers in the broader printing landscape, it helps to compare them with inkjet and laser printers—the two dominant technologies. Each type of printer has strengths and weaknesses, and examining these side by side shows why solid ink remained a niche choice rather than a mass-market option.

This comparison also highlights where solid ink printers excelled and where they fell short, giving readers a clearer idea of whether they could meet specific printing needs.

Solid Ink vs. Inkjet Printers

Inkjet printers are the most common choice for households and small offices, largely because of their affordability and wide availability. Compared to solid ink printers, inkjets typically have a lower initial purchase price and are easier to set up. However, ongoing costs—especially for replacement cartridges—can add up quickly, often making inkjets more expensive in the long run.

On the other hand, solid ink printers tend to offer better color vibrancy and higher consistency across large print runs. For example, a marketing team producing a batch of colorful brochures would likely notice richer tones from a solid ink printer compared to a standard inkjet. Still, for everyday users printing occasional documents, the higher upfront cost and warm-up time of solid ink printers make inkjets the more convenient option.

Solid Ink vs. Laser Printers

Laser printers dominate the office market thanks to their speed, durability, and cost-effectiveness at high volumes. They are designed to churn out thousands of pages each month with minimal downtime, something solid ink printers could not always match. For businesses that value speed and sharp text above all else, lasers remain the clear winner.

Where solid ink printers stood out, however, was in color reproduction. While laser printers excel at crisp black-and-white documents, their color output often looks more muted compared to the bold, glossy results of solid ink. Creative professionals sometimes favored solid ink models for this reason, although the risk of smudging and heat sensitivity remained a tradeoff.

Solid Ink vs. Emerging Ink Tank Printers

In recent years, ink tank printers have gained popularity, especially in Asia and emerging markets. These printers use refillable tanks instead of disposable cartridges, making them far more economical over time. The combination of low cost per page, long-lasting ink supplies, and decreasing printer prices has made ink tank models attractive for both homes and businesses.

Against this backdrop, solid ink printers began to look less competitive. While they still offered eco-friendly packaging and strong print quality, ink tank systems achieved similar cost savings with fewer drawbacks like warm-up delays or print durability concerns. As a result, ink tank printers became a more sustainable and practical option for many buyers.

Solid Ink Printers vs Inkjet, Laser, and Ink Tank: Key Differences

| Printer Type | Strengths | Weaknesses | Best For |

|---|---|---|---|

| Solid Ink | Vibrant color quality, eco-friendly ink sticks, consistent output | Long warm-up time, higher upfront cost, prints can smudge | Offices needing bold, colorful prints |

| Inkjet | Low purchase price, compact size, good photo quality | High ink cost, cartridges run out quickly, slower for bulk jobs | Home users, light printing, photos |

| Laser | Fast print speeds, sharp text, cost-effective for high volume | Muted colors, bulkier design, higher toner waste | Businesses needing speed and volume |

| Ink Tank | Very low cost per page, refillable tanks, long-lasting ink supply | Slower than lasers, higher initial price than inkjets | Homes and offices seeking economical, long-term use |

Use Cases and Ideal Scenarios for Solid Ink Printers

Although solid ink printers never dominated the global market, they carved out a niche where their unique strengths proved valuable. Their vibrant color output and eco-friendly design made them attractive to certain industries and organizations that prioritized visual quality and sustainability.

Understanding these use cases not only highlights why businesses adopted them in the past but also explains where they might still be relevant today, despite the rise of newer printing technologies.

Marketing and Graphic Design Departments

For teams producing brochures, flyers, or presentation materials, solid ink printers were an appealing option. The output quality—rich, saturated, and glossy—helped make marketing content more engaging. Many design professionals appreciated how colors printed with solid ink appeared almost “wet look,” giving documents a premium feel compared to inkjet or laser output.

In practice, this meant a small business could print short-run marketing materials in-house without needing to outsource to professional print shops. While large-scale production still favored offset printing, solid ink printers bridged the gap by offering high-quality results at the office level.

Schools and Educational Institutions

Educational environments often need a mix of text-heavy documents and colorful teaching aids. Solid ink printers fit well here because they could produce vivid charts, posters, and handouts that captured student attention. Teachers could rely on the consistency of output for class materials, while administrators valued the eco-friendly ink sticks that reduced waste.

Some schools also appreciated the predictable cost-per-page, which helped manage tight budgets. Instead of constantly replacing costly ink cartridges, solid ink provided thousands of prints per set of sticks, reducing financial and logistical strain on staff.

Businesses Focused on Sustainability

Organizations with strong sustainability goals often leaned toward solid ink printers because of their minimal packaging waste. Unlike bulky plastic cartridges, ink sticks came in compact blocks that were almost entirely consumed during printing. This aligned with corporate social responsibility initiatives where reducing landfill waste was a priority.

For companies wanting to highlight their green credentials, using solid ink printers also became part of their branding. For example, an eco-friendly startup could reinforce its values not only in its product offerings but also in how it managed daily operations, including office printing.

Offices with Moderate but Regular Printing Needs

Solid ink printers were not the fastest machines on the market, but they worked well for businesses with steady, medium-volume workloads. An office producing training manuals, client proposals, or internal newsletters could benefit from the balance of print quality and cost efficiency.

In this context, the warm-up time was less of an issue because jobs were usually sent in larger batches rather than as one-off pages. Once the printer was running, it delivered consistent performance and reliable color quality throughout the print cycle.

Real-World Performance and Case Studies

Specs and features only tell part of the story. To see how solid ink printers really stacked up, it helps to look at real offices, classrooms, and user feedback that highlight their strengths and frustrations.

Business Use Cases

Small businesses often found solid ink printers useful for producing marketing materials in-house. For example, a local design studio or a small travel agency could create colorful brochures, posters, or flyers without outsourcing to a professional print shop. The vibrant color reproduction and consistency across batches helped these companies present a polished image while keeping costs predictable. In many cases, this capability gave them more control over branding and turnaround times.

Large enterprises with sustainability targets also adopted solid ink printers. Some corporations valued the eco-friendly design, particularly the reduced packaging waste compared to traditional toner cartridges. For organizations publishing internal newsletters, training manuals, or customer-facing documents, solid ink provided both quality and environmental benefits. The predictable yield of the ink sticks also made budget planning easier, something enterprise IT managers often highlighted when comparing to inkjet fleets.

User Experiences and Reviews

Professional reviewers often praised solid ink printers for their bold colors and simplicity. According to PCMag and TechRadar, they consistently delivered output that rivaled or even surpassed many mid-range inkjets. Reviewers also noted that loading ink sticks was far less messy than dealing with liquid cartridges or toner refills, a point that everyday users appreciated in office settings.

On the other hand, user forums like r/printers on Reddit reveal some practical frustrations. Many owners complained about the long warm-up times, with some saying it took several minutes just to print a single page. Others shared that prints could smudge if handled immediately after printing or exposed to heat. These mixed experiences highlight the gap between professional test results and the realities of daily office use, showing why solid ink printers appealed strongly to some but frustrated others.

Future of Solid Ink Printers

The future of solid ink printers has been a subject of debate among technology observers. Once considered a revolutionary alternative to both inkjet and laser printers, the technology has gradually declined in mainstream adoption. However, the underlying innovations continue to influence modern printing, and some organizations still rely on existing models for their unique benefits.

By looking at industry trends, market demand, and sustainability priorities, we can better understand whether solid ink printers still have a place in the evolving printing landscape.

Decline in Mainstream Adoption

Over the last decade, the printer market has shifted significantly toward laser and ink tank models, leaving little room for solid ink printers to grow. Xerox, the primary company behind this technology, has gradually reduced its focus on new models, signaling that large-scale development is unlikely.

Part of the decline stems from limitations that were never fully resolved—such as long warm-up times, durability concerns, and limited manufacturer support. For most buyers, these drawbacks outweighed the benefits, especially as competing technologies became more efficient and affordable.

Influence on Printer Innovation

Despite their decline, solid ink printers left a lasting impact on the industry. The focus on sustainability—through minimal packaging and nearly zero ink waste—paved the way for greener printing solutions. Many of the ideas pioneered in solid ink technology can now be seen in refillable ink tank systems and efforts to reduce cartridge waste across the industry.

Even the emphasis on vibrant, consistent color output has influenced how manufacturers position premium inkjet and laser models today. Features such as higher resolution, enhanced color saturation, and long-term cost efficiency echo principles that solid ink technology introduced years ago.

Niche and Legacy Usage

While new models are rare, some organizations still maintain solid ink printers in their workflows. For example, design studios or schools that invested in the technology may continue using them as long as supplies remain available. For these users, the benefits—especially color vibrancy and eco-friendly operation—still outweigh the downsides.

However, reliance on legacy devices poses risks. As support and parts become harder to find, maintenance costs can rise, making long-term use less practical. Over time, most remaining solid ink printer owners may need to transition toward newer alternatives such as ink tank systems.

Future Printing Technology Trends Compared to Solid Ink Printers

| Technology | Future Outlook | Key Focus | Comparison to Solid Ink Printers |

|---|---|---|---|

| Solid Ink Printers | Limited adoption, legacy use only | Eco-friendly printing, vibrant color | Declining market, but influenced sustainable design in modern printers |

| Laser Printers | Continued dominance in offices | Speed, high-volume efficiency | More durable and widely supported than solid ink |

| Inkjet Printers | Strong presence in home & photo printing | Compact size, photo-quality output | More affordable but less eco-friendly than solid ink |

| Ink Tank Printers | Rapid global growth, especially in Asia | Low cost per page, refillable tanks | Achieves eco-friendly and cost efficiency without warm-up drawbacks |

| 3D Printers | Emerging technology with niche use cases | Prototyping, manufacturing | Different category, but shows how printing innovation evolves beyond paper |

Conclusion

Solid ink printers occupy a fascinating place in the history of printing technology. They were never the most popular choice, but they demonstrated how innovation could challenge long-standing models like inkjet and laser. By focusing on eco-friendly design and vibrant print quality, they carved out a loyal user base among schools, creative teams, and businesses that valued color impact and sustainability.

At the same time, their limitations—particularly warm-up delays, durability concerns, and limited manufacturer support—prevented them from reaching mainstream success. As laser and ink tank printers continued to evolve, solid ink technology gradually fell into decline, surviving mostly in legacy usage and as an influence on newer, greener printing methods.

For anyone studying printers today, solid ink models remain a reminder that the “best” technology isn’t always the one that dominates the market. Sometimes, innovations serve as stepping stones, shaping future designs even if they don’t endure on their own. In that sense, the legacy of solid ink printers continues—visible not in new product launches, but in the way modern printing emphasizes sustainability, efficiency, and long-term value.

FAQs About Solid Ink Printers

What are solid ink printers?

Solid ink printers are a type of printing device that uses solid blocks of wax-like ink, which are melted and applied directly onto paper. This technology is known for producing vibrant, glossy colors and reducing packaging waste compared to traditional cartridges.

What happened to solid ink printers?

Solid ink printers peaked in popularity during the 2000s, mainly through Xerox models, but eventually declined as ink tank and laser printers became more affordable and efficient. While some organizations still use legacy machines, new models are no longer widely produced.

What are the advantages of solid ink?

The main advantages of solid ink include high-quality color output, eco-friendly ink sticks with minimal packaging, and consistent performance over long print runs. Businesses focused on sustainability or producing marketing materials often valued these benefits.

What are the disadvantages of solid ink?

Is solid ink printing expensive?

Solid ink printers often had a higher initial purchase price, but their cost per page was competitive, sometimes even lower than inkjet cartridges. However, with limited market availability today, maintaining these printers can become costly due to scarce supplies and parts.

Is solid ink printing expensive?

Solid ink printers often had a higher initial purchase price, but their cost per page was competitive, sometimes even lower than inkjet cartridges. However, with limited market availability today, maintaining these printers can become costly due to scarce supplies and parts.